What is A Rivet Nut?

How Do Rivet Nut Work?

Rivet nuts are a combination of a blind rivet and a welded nut.When the material is too thin to hold bolts or screws, the use of rivet nuts can be attached to the surface of the steel plate for bolting.Rivet nuts can be applied to the single side of the part to use, rivet nuts attached to the thin metal pre-positioning device, through the cold extrusion deformation to achieve excellent thin-wall riveting, sealing riveting and single-sided riveting, and so on.

Rivet nuts mainly through the rivet nut gun to rivet, more suitable for square tube round tube and other places where it is not easy to pressure rivet operation. Rivet nuts can be very good to make up for the shortcomings of electric welding welding.It will also be a good improvement in terms of aesthetics in places that are not easy to weld, such as thin plates.

How Do You Install A Rivet Nut ?

In the past, it was a hassle to install a pull rivet nuts. But with the development of technology, there are special tools for installing rivet nuts.The Rivet Nuts Tool makes the process of installing rivet nuts simple and wonderful.

Here’s a simple step-by-step procedure for installing rivet nuts:

- Place the rivet nuts onto the mandrel of the rivet nut gun.

- Place the rivet nuts into the place where it is to be installed (drill the holes in advance). Start the rivet nuts tool to pull the rivet nut.

- At this point the rivet nut has deformed. And a tight joint has been formed on the blind side of the material.

- Take the rivet nuts tool out of the rivet nuts. (Some rivet nuts tools can automatically reverse out of the rivet nuts)

Rivnuts VS Nutserts VS Rivet Nuts

These names are really just different names for rivet nuts.Essentially both are referring to rivet nuts.In different companies, in different countries, in different regions, people may call it differently. Over time, these names have become the default product names.

What Are The Benefits Of A Rivet Nut?

Rivet nuts replace the traditional weld nuts, making up for the shortcomings of thin metal plates, thin tubes that are easy to melt and weld nuts that are not smooth. Rivet nuts provide an economical, fast and reliable riveting system and have many advantages over other fasteners (nuts or bolts).

- Can be mounted unilaterally without access to the rear.

- Rivet nuts can be installed quickly without training.

- A permanent strong thread can be formed for attaching bolts/screws.

- Provides a fast and cost effective connection with high load carrying capacity.

- Installation of rivet nuts will not damage the surface of the workpiece, plating, not easy to deform.

- It has strong corrosion resistance, strong torsion resistance and good tensile strength.

- Rivet nuts mounting is safer. No harmful gases, heat or dust are generated.

- Light weight, good strength, series of specifications (can be customised)

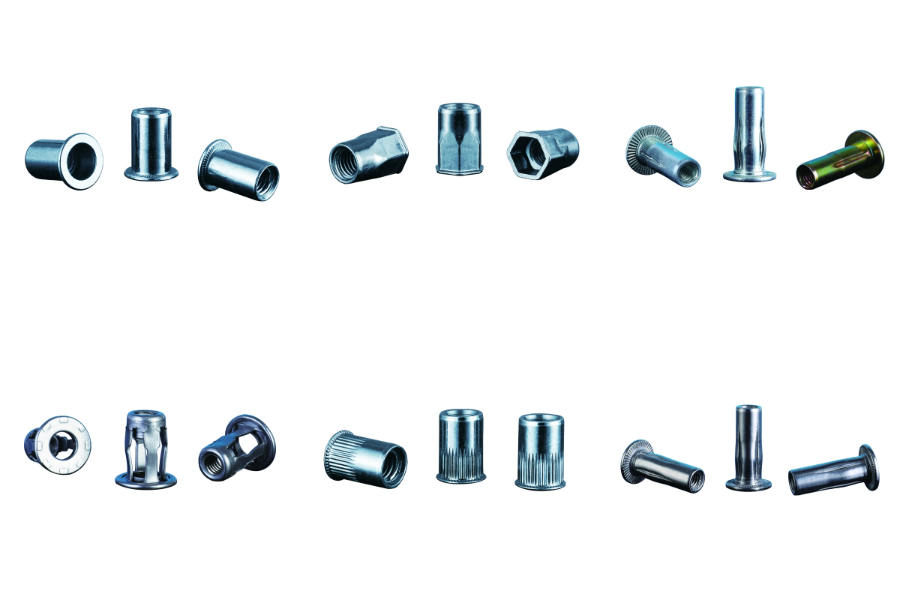

What Are The Different Types Of Rivet Nuts?

There are different types of rivet nuts for different applications. There are three main body types and special rivet nuts.

Flat Head Rivet Nut

Flat head rivet nuts are the most common and strongest type of rivet nuts. The shape of the head is flat. Depending on the cylindrical texture of the rivet nuts, it can be classified as glossy or vertical. Among them, the vertical thread type rivet nuts are more common in use, because the vertical thread can play a non-slip role in the riveting process. Installation can be directly open round hole.

Countersunk Head Rivet Nut

Countersunk head rivet nuts have a 90° or 120° angle on the profile and are classified into two types: smooth surface and vertical stripe. Most countersunk head rivet nuts are riveted into thin plates with chamfers. In addition to the hole, a small chamfer is required in the head area during installation, and the head is parallel to the sheet after installation.There are also small countersunk head rivet nuts, which you can tell from the name is that the outer diameter and thickness of the head is smaller than the countersunk head rivet nut. If the sheet metal itself is thin and the chamfer is small or no chamfer is made, only the small countersunk head rivet nuts are applicable.

Hex Head Rivet Nut

Hexagonal rivet nuts are divided into flat head hexagonal rivet nuts and small head hexagonal rivet nuts.In terms of material, it can be classified as zinc-plated iron, 304 stainless steel, 316 stainless steel, etc. Rivmate can supply sizes from M3-M12.Installation of hexagonal rivet nuts requires a hexagonal hole because the hexagonal rivet nuts have a hexagonal shape. Hexagonal rivet nuts are very effective in preventing slippage and can withstand greater torque.

Special Rivet Nut

To cope with the specific needs of different applications. There are many other special types of rivet nuts that have been invented. For example, Jack nuts, slotted rivet nuts and so on.

According to different criteria, rivet nuts can be divided into many types.

Classification of rivet nuts:

By material: Carbon steel, stainless steel, aluminium, copper

By Head Shape: Flat head rivet nuts, small head rivet nuts, countersunk head rivet nuts, hexagon head rivet nuts.

By rod shape: Round body rivet nuts, Full hexagonal rivet nuts, half hexagonal rivet nuts,

By thread: Metric Thread Rivet Nuts, UK Thread Rivet Nuts, US Thread Rivet Nuts

By closure or not: Closed end rivet nuts, Open end rivet nuts

Choosing the Right Installation Tool For Rivet Nuts

There are a total of three mainstream rivet nut tools on the market today, namely pneumatic rivet nut guns, electric rivet nut guns and manual rivet nut tools. The specific choice of which rivet nut tool to use depends on the size of your project, and the specific application.

Pneumatic rivet nuts tool: Pneumatic rivet nuts tools are one of the most convenient and fastest methods for industrial production.In industrial grade manufacturing processes, pneumatic rivet nut tools allow for fast and stable installations with consistent results. Advantages of pneumatic rivet nuts installation tools include:1. The tool can be rotated automatically during insertion of the rivet nut and pulling out of the rivet nut without the need for physical effort.2. The tool can be set to a fixed pressure and stroke to ensure consistency of installation.Disadvantages : Pneumatic rivet nut tools require an air source, which can restrict movement and make remote use less practical.

Electric Rivet Nuts Tool: The convenience of an electric rivet nut gun works well for everyday use. If the amount to be riveted is small, an electric gun is an ideal choice. The advantage of the electric rivet nuts gun is that it can be easily carried. The disadvantage is that it is not suitable for industrial use and the battery limits the number of times it can be used.

Manual rivet nuts tool: Hand tools are the least expensive type of tool. Advantages include being inexpensive and ideal for people who like to get their hands dirty. Disadvantages: require the operator to use physical strength to use them. Not suitable for bulk use.

Applications of Rivet Nut

In fact, there is no fixed place for the application of rivet nuts, basically every field will use rivet nuts.Rivet nuts can be used whenever the workpiece resembles a thin plate or sheet metal.Currently rivet nuts are widely used in chassis cabinets, automotive, aviation, railway, refrigeration, lifts, instruments and other types of light industrial assembly.Can solve the metal, thin tube easy to melt, tapping internal threads easy to slip teeth and other issues, riveting nuts do not need to tap the internal threads, do not need to weld the nut, riveting solid high efficiency, easy to use.

Submit Your Sourcing Request

Please complete the form below and our customer support team will be in touch with you shortly. Inquiries submitted through this form will receive priority processing over emails.