Table of Contents

Tesla Rivets are an important part of Tesla. So do you know what are the specific scenarios where Tesla rivets are used on a Tesla? Let’s come together to understand it!

Table of Contents

What are Tesla Rivets?

Tesla rivets are a type of fastener. It used in the manufacturing process of Tesla vehicles to connect several key parts such as the body, chassis, powertrain and interior components. These rivets include a variety of types, such as Blind Rivets, Structural Rivets, Self-Piercing Rivets (SPR), and Lockbolts. Each type of rivet plays a specific role in different application scenarios. It can ensure the overall strength, durability and safety of the vehicle.

Types of Tesla Rivets

A safe automobile uses a large number of fastener products in its production. Rivets are one of those very important components. However, there are many types of rivets that correspond to different conditions and scenarios of use, and not all of them are used on the Tesla. Below are some examples of the types of rivets commonly used in Tesla.

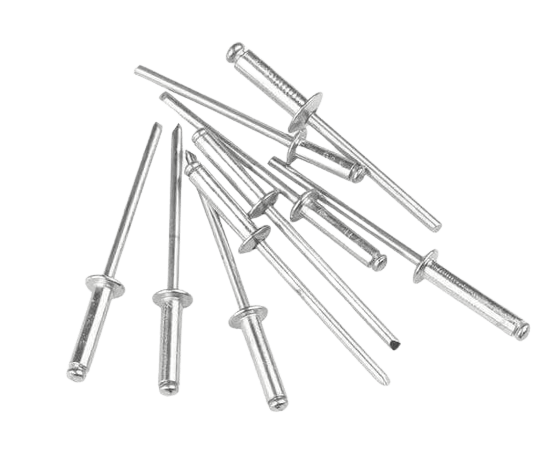

Blind Rivets

Blind rivets are able to be installed from one side, making them ideal for use in interior bodywork and hard-to-reach areas. Blind rivets are often used to attach Tesla’s exterior body panels such as doors, roof and side panels. It provides panel strength while maintaining panel aesthetics.

Self Piercing Rivets(SPR Rivets)

Self piercing rivets (SPR Rivets) are a new type of joint fastener. Aluminum alloys are widely used on Tesla for lightweighting purposes, and SPR Rivet is used to connect aluminum body panels to the frame. It does not require pre-drilling and provides a strong bond.

Spr rivets can join aluminum and steel materials and ensure a strong connection between them. spr rivet is very suitable for mass production activities, it can be fully automated and mechanized, which saves a lot of labor and time costs while achieving lightweight body structure!

Structural Blind Rivets

A competent Tesla car has more than just regular connections, but also connections that need to withstand high stress areas. Structural blind rivets are used to accomplish this. It is used to connect load-bearing components such as the suspension and critical nodes of the drivetrain.

A competent automobile manufacturer will invest more cost in the protection of the vehicle. Tesla is no exception, and it uses high-strength structural core-pull rivets for the installation of its safety devices and protective components to ensure that people can be minimally injured in the event of a crash.

High-strength rivets provide extremely high shear and tensile strengths and can withstand high-frequency mechanical stresses to prevent failure due to fatigue.

Rivet Nuts

Rivet nuts are mechanical fasteners that connect thin sheet structures and provide threaded attachment points. It is commonly used for threaded connections in thin-walled structures such as Tesla’s interior body mounts and panel mounts. rivet nuts provide an excellent means of repair and provide a reliable threaded connection point in areas that require frequent disassembly.

Rivet nuts are flexible enough to be applied to a wide range of materials and thicknesses, and are widely used in the fixing of bodywork and interior components!

Lockbolts

Lockbolt Rivet is a type of rivet that can provide extra strength. It tends to be used in connecting Tesla’s critical structural components such as the body frame and chassis in high stress areas. Or it is used to secure key components of the powertrain, such as battery packs and motor mounts, and it ensures the safety and stability of the powertrain.

The extremely high strength of the Lockbolt rivet ensures that critical components are securely attached and remain stable under conditions of high vibration and dynamic loads without loosening.

Applications of Tesla Rives

这是测试文本,单击 “编辑” 按钮更改此文本。

Tesla Body Connections

In the case of the Model 3, for example, its body structure uses blind rivet and spr rivet for attachment and assembly.

Tesla’s door panels can’t be connected from both sides in order to maintain structural integrity and aesthetics. And Blind rivet solves this problem perfectly. the biggest advantage of Blind rivet is that it can be connected on one side without accessing the back side of the material. the head of Blind rivet is flat after installation, which won’t affect the appearance of the door, and ensures that the panel will not come loose while the vehicle is in motion.

Tesla uses spr rivet for all of its body-face-to-steel-frame connections. To avoid galvanic corrosion and to simplify the installation process. Spr rivets are used, which do not require pre-drilling. They penetrate and connect aluminum and steel, providing a strong and reliable connection. It avoids corrosion problems caused by the contact of different metals and realizes the light weight involved.

Tesla Interior Fixed

As an example, the model s of the Tesla Motors lineup uses a lot of blind rivets for its interior assembly.

Tesla’s interior components need to be mounted quickly, securely and aesthetically, and the Blind Rivet fulfills this requirement. The engineers only need to use a special blind rivet gun to quickly install the blind rivets. And the blind rivet ensures that the connection between the Tesla’s dashboard and center console is very strong.

Tesla Chassis Structural Connections

The car chassis supports the weight of the entire car, so it is very important that it is stable.

Take Tesla’s Model X for example, it uses a large number of high-strength structural rivets and blind rivets for its chassis and battery pack.

Tesla’s chassis and battery pack require high strength because they have to withstand the shock and vibration of the vehicle in motion. That’s why engineers use high-strength structural rivets for this installation process. High-strength structural rivets can provide extremely high shear and pulling forces, which can ensure the solidity and durability of the chassis structure and battery pack mounts.

In order to protect the battery pack and floor pan components, chassis guards are used to secure them. This component does not need to be subjected to high levels of strength, so a large number of blind rivets are used to secure it. Blind rivets provide a strong connection and are very easy to install, ensuring that the shield will not loosen or fall off while driving.

Tesla Powertrain Connection

The powertrain is the heart of the car! If you want a car to be like a beast, then the powertrain must not be bad!

Take the Model Y for example. Tesla’s powertrain has high load and vibration requirements, the powertrain generates high loads and high vibrations. Engineers generally use lockbolt rivet to connect the motor mounts to the driveshaft. Which provides extremely high shear and pulling forces to ensure that the motor mounts and driveshafts are very strong under all kinds of working conditions. It prevents them from loosening or shifting!

Pros and Cons of Using Rivets in Tesla

Tesla’s use of rivets in the manufacturing process offers many benefits. Including high strength, light weight, multi-material connections, quick installation, aesthetics and high reliability. These advantages help increase productivity, optimize body structure, and enhance vehicle performance and appearance. However, rivets also have some drawbacks.Such as difficulties in repair and maintenance, high equipment and tooling costs, lower flexibility, and high hole size requirements. Let’s take a closer look at the pros and cons of Tesla rivets.

Pros of Blind Rivets in Tesla:

- High Strength and Stability: The high shear and pull-out forces provided by rivets are critical to the overall safety and durability of the vehicle, especially in high stress and high vibration environments.

- Lightweight design: Aluminum and titanium alloy rivets, with their light weight, help to achieve a lightweight design for the vehicle, improving energy efficiency and range.

- Multi-material connection: Self-pierce rivets (SPR) are particularly suitable for connecting different materials, allowing flexibility in the use of a variety of materials to optimize the body structure and improve performance and durability.

- Fast and Efficient Installation: Rivet installation is often faster and more efficient than other methods such as welding, which improves the efficiency of production lines, shortens manufacturing time and reduces production costs.

- Aesthetics and Neatness: Rivet installation results in a flat head and neat appearance without affecting the aesthetics of the body and interior. Enhances the overall appearance quality of the vehicle and user experience.

- Reliability and durability: Rivet connection has high reliability and durability, which can ensure the stable performance of the vehicle during the whole service life and reduce the maintenance frequency and cost.

Cons of Blind Rivets in Tesla:

- Difficulty of repair and maintenance: Rivets are permanent connections that require destructive methods (e.g. drilling or cutting) for removal and cannot be reused. This increases the difficulty and cost of repairing and replacing rivets. Especially in the event of an accident or when parts need to be replaced.

- Less flexible: Compared to bolted connections, riveted connections are less flexible when adjustments or repositioning is required. It requires higher precision and planning during design and assembly and lacks the flexibility to be adjusted at a later stage.

- Higher requirements for hole size: rivet connections require higher hole sizes for pre-drilled holes. Too large or too small a hole size will affect the quality of the connection.

Order Tesla Rivets for Yout Tesla Project. Rivmate can Help You!

Tesla rivet is not just used only on tesla’s cars, but also on various brands of cars all over the world. So no matter what type of car, there are tons of rivets present on it.

Do you want to order tesla rivets for your automotive project? Contact Rivmate! Rivmate has been vetted by Tesla and has become one of Tesla’s rivet suppliers! So you can have complete confidence in the quality of the rivets! Our rivets can meet the requirements of any automobile manufacturer in the world.

Whether you are looking for standard blind rivets, high strength structural rivets, or specialty rivets. You can buy them all from Rivmate! Rivmate is the top pop rivet manufacturer in China, if you want to buy blind rivets, contact us now!