Lockbolt vs Rivet: Comprehensive Comparison and Usage Guide of Lockbolt

There are many fasteners used in manufacturing and construction to ensure the strength and reliability of products and structures. Locking bolts and rivets are common types of fastening, and they have their own features and benefits. Whether you are a dealer doing a construction project, or a contractor for a building, understanding the differences between locking rivets and rivets and the scenarios in which they are used will help you make an informed choice.

In this article, we will provide a comprehensive comparison of locking rivets and rivets, as well as a detailed guide to their use, to help you understand how they work, their features and their advantages. We hope that this article will address your questions and will be helpful to you in your projects.

Table of Contents

Lockbolt vs Rivets

Lockbolt rivets and common rivets differ in the way they are joined and the conditions in which they are used; Lockbolt rivets offer greater strength and reliability and are used in situations where high loads are required. The common rivet is a common and widely used connector for general joining needs. The choice of connection depends on the specific application requirements and material properties.

What is a lockbolt ?

The Lockbolt rivet is a mechanical joint often used in applications where high strength and reliability are required. It can join two or more materials.The Lockbolt rivet consists of two main parts: the rivet and the collar.

A rivet is a hollow bolt with a head, usually made of a high-strength material such as steel or aluminum alloy. The end of the rivet bolt usually has threads or ridges for mating with the locking ring.

The locking ring is a ring-shaped metal sleeve, usually made of steel. It has an internal locking groove or recess that matches the threads or ridges of the rivet bolt.

How do Lockbolt Rivets Work ?

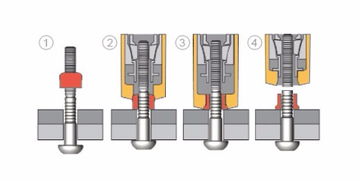

The Lockbolt rivet works by tightening and joining by the mechanics of the locking ring.

During the installation of a lockbolt rivet, when the locking ring is pushed onto the end of the rivet and turned, it expands and locks onto the rivet. This locking mechanism makes the connection stronger and less likely to loosen or come loose. The locking groove or notch of the locking ring interacts with the structure of the rivet bolt threads or ridges to provide additional resistance and support, making the connection more stable.

The working principle of the Lockbolt rivet gives it high strength and reliability for applications that require high tensile or shear forces. That’s why it’s commonly used in aerospace, railroad, automotive, construction and marine applications to connect structural members, panels, frames and other components to provide strength and reliability.

What is a rivet ?

A rivet is a commonly used riveting fastener used to securely join two or more materials together. It consists of two main parts: the rivet body and the rivet cap.

In most areas, rivets can replace welding, gluing, and other joining methods, and can provide excellent joining strength. However, compared to the lockbolt rivet, the strength is much lower, so the lockbolt rivet is often used in applications that require a strong connection.

Characteristics of Rivets and Lockbolt Rivet

The lockbolt rivet is a special type of rivet, so it has many of the features of a rivet, but it is much stronger than a rivet. lockbolt rivets are often used in scenarios that require high strength. So what are the characteristics of each of them? What are the differences between them? I have listed the differences between the lockbolt rivet and the rivet in the table below. I hope it will be helpful for your project.

| Specificities | Lockbolt Rivet | Rivet |

|---|---|---|

| Working Principle | Fastening and connection by means of the mechanics of the collar | Connection by deformation of the rivet by pressure |

| Installation Methods | Requires special tools for installation | Suitable for rivet gun or hand tool installation |

| Field of Application | Applications that require high strength or shear forces. Such as aviation, railroad, automotive, construction and marine. | It is widely used in a variety of industries, including automotive manufacturing, construction, and electronic equipment. |

| Strength and Reliability | Provides high strength and reliable connections | Connections that provide general strength and reliability |

| Anti-loosening Performance | Good anti-loosening properties, good resistance to vibration and shock | Good anti-loosening properties, good resistance to vibration and shock |

| Installation speed | Faster installation | Relatively slow installation |

| Cost | Generally higher | Generally lower |

Lockbolt vs Rivet: Strength and Reliability Comparison

Lockbolt Rivet

Lockbolt rivet offers significant advantages in terms of strength and reliability.

Lockbolt rivet provides a high strength connection. The unique working principle allows Lockbolt rivet to withstand high tensile and shear forces. When manufactured from corrosion-resistant materials, such as stainless steel or aluminum alloys, lockbolt rivets can be adapted to different working environments and material requirements. This makes Lockbolt rivet the connection of choice for many heavy duty applications.

Rivet

Rivets are usually lower in strength. They form a connection through deformation of the rivet, but they have a lower connection strength compared to lock rivet bolts. As a result, common rivets may not provide sufficient strength in applications where high tensile or shear forces are required.

Rivets are used in a wide variety of industries, including aerospace, automotive manufacturing, construction, and electronic equipment. They are primarily used for general joining needs and are not subjected to extremely high loads or harsh working environments.

Lockbolt vs Rivet

Lockbolt rivet is superior to ordinary rivets in terms of strength and reliability. It provides a high-strength connection with good resistance to loosening for applications that require high loads, vibration and shock. Regular rivets are suitable for general joining needs, but in scenarios where higher strength and reliability are required, Lockbolt rivet may be a better choice.

Lockbolt vs Rivet: Applications Comparison

Applications of Lockbolt Rivet

- High-load applications: Lockbolt rivet is used in applications that require high tensile or shear forces, such as aerospace, railroad, automotive, construction and marine applications.

- Requires high strength connections: Because Lockbolt rivet provides high strength connections, it is often used in applications that require reliable and durable connections that can withstand severe service conditions.

- Requirement of anti-loosening: The mechanical locking principle of Lockbolt rivet makes it anti-loosening and suitable for vibration and shock environments.

Applications of Rivet

- General connection needs: Rivet is used in a wide variety of industries including aerospace, automotive manufacturing, construction and electronics. They are primarily used for general joining needs and do not need to be subjected to extremely high loads or harsh working environments.

- Quick Installation: Because Rivet is relatively easy to install, the process can be accomplished quickly using a rivet gun or hand riveting tool, making it suitable for scenarios where efficient installation is required.

- Affordable: Compared to Lockbolt rivet, Rivet is generally less costly, making it suitable for projects with limited budgets.

Lockbolt vs Rivet: Comparison of Installation and Maintenance

There are some differences between Lockbolt rivet and Rivet in terms of installation and maintenance:

Installation:

Installation of the Lockbolt rivet is a bit more complicated and usually requires the use of specialized installation tools. These tools provide the correct installation force and angle to ensure a correct and stable connection. The installation process may require some additional time and skill.

Rivet installation is relatively simple. Using a rivet gun or hand rivet tool, the installation process can be completed quickly.

Maintenance:

Once the Lockbolt rivet is installed, it generally requires only occasional maintenance. However, if looseness or other problems are found, the lockbolt rivet may need to be replaced or reinstalled.

Rivet is relatively simple in terms of maintenance. If a connection becomes loose, it can be repaired by re-riveting or replacing the rivets.

Lockbolt Rivets VS Rivets: Comparison of Economic Costs

Compare the economic cost of lockbolt rivet and rivet. Several factors need to be considered, namely the cost of purchase, the cost of maintenance, the cost of installation. I have made a comparison of their economic costs in the table below. It’s easy for you to quickly understand the difference in their costs.

| Lockbolt Rivet | Rivet | |

|---|---|---|

| Installation Cost | High | Relatively Low |

| Maintenance Cost | Relatively Low | High |

| Cost of Purchase | High | Relatively Low |

| Transportation Cost | / | / |

Of course, in the real purchasing process, the comparison of economic costs depends not only on the purchase cost, but is also influenced by factors such as specific application requirements, project budget and service life. So when making a choice, you need to consider the performance, reliability and economic cost of the connection and make a trade-off based on specific needs.

Final Thoughts

The lockbolt rivet is considered a type of rivet. Compared to a rivet, a lockbolt rivet has a higher economic cost, but it can provide a stronger connection and can handle scenarios that a normal rivet cannot. And lockbolt rivet requires only occasional maintenance. As far as I can see lockbolts have no drawbacks except for the higher price.

So when it comes to scenarios that require riveting, how do you choose? Actually it is very simple, if your project has higher requirements for strength, such as bridge connection, ship connection, etc., you choose lockbolt rivet. if your project is just a general connection needs, such as furniture connection, plate connection, etc., you can choose ordinary rivets.

There is a good saying. There is no such thing as the most expensive or cheapest rivet fastener, only the most appropriate rivet fastener.

Looking for Lockbolt Rivet? Rivmate can help!

Are you looking for lockbolt rivet manufacturers or rivet manufacturers? If you want to import high quality but affordable lockbolt rivet and rivet wholesale from China, then you can absolutely contact Rivmate Rivet.

Rivmate is one of the top blind rivets manufacturers and suppliers of lockbolt rivet in China. You can get various sizes, materials and specifications of rivets from Rivmate. If your project needs customized rivets, don’t worry, Rivmate as a factory can provide professional customized rivet solutions for you. Want to know more? Contact us now!