How to Measure Blind Rivets? Ultimate Guide to Measuring Rivets

Blind rivets are a very convenient and fast fastener for connectors. They are widely used in industries and fields such as automotive manufacturing, aerospace, construction and furniture making. In order to ensure that blind rivets are connected accurately, it is important to measure their dimensions and parameters correctly. Do you know how to measure blind rivets? This article will provide you with a comprehensive guide that will teach you how to measure blind rivets accurately. Ensure that your project has the most secure connections possible.

Table of Contents

Preparation Before Measuring Blind Rivets

Before measuring blind rivets, you need to prepare the following tools and materials:

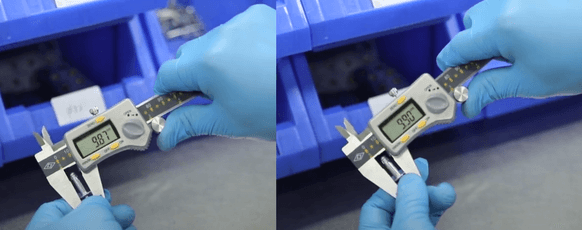

- Calipers: for measuring the length and diameter of the blind rivets.

- Thread gauge: for measuring the type of threads of the blind rivet.

- Mold or Measuring Tool: Used to measure the shape of the head of the blind rivet.

How to Measure Blind Rivets?

Blind Rivets are generally categorized into three head types – Dome Head, CSK Head, and Large Flange Head. There are some differences in measurements between different head sizes.

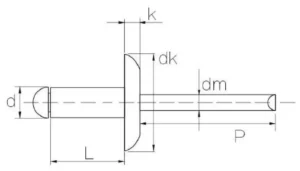

Dome Head and Large Flange Head

d : Diameter

L : body length

dk : rivet head dimeter

k : rivet head thickness

dm : mandrel diameter

p : mandrel reveal

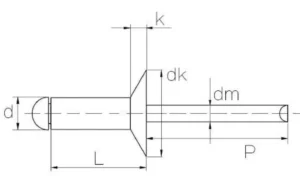

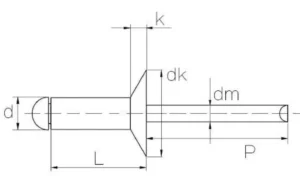

CSK Head (Countersunk Head)

d : Diameter

L : body length

dk : rivet head dimeter

k : rivet head thickness

dm : mandrel diameter

p : mandrel reveal

After understanding the parameters of blind rivets, let’s learn more about how to measure blind rivets.

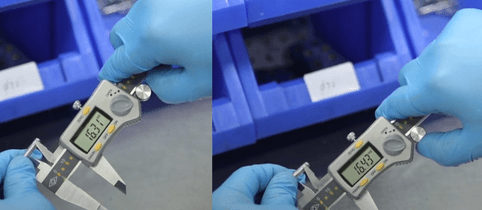

How are the Diameters of a Rivet Measured? (d)

The diameter of the blind rivet is an important parameter that affects the strength of the connection and the selection of the right size. It plays an important role in the strength and robustness of the connection, the effectiveness of the core extraction, material suitability and installation requirements.

When measuring the diameter of a blind rivet, the topmost part of the rivet should be measured, not the mandrel or head width.

The diameter of the blind rivet should be measured several times and averaged. This will help to calculate the correct size of the blind rivet.

Please note that the diameter of blind rivets is usually measured in millimeters (mm).

How to Measure Rivet Length ? (L)

Selection of the appropriate blind rivet length ensures the range of connections, penetration capability, core pulling effect and safety of the installation, resulting in a high quality connection. The length of the Blind Rivet varies depending on the use and requirements.

When measuring the length, you need to keep the surface of the blind rivet clean and perpendicular to the measuring tool. You need to select the appropriate Blind Rivet length. A blind rivet that is too long may fail to install or cause damage to the material being installed or to objects behind the hole.

How to Measure Rivet Head Diameter ?

The rivet head of a blind rivet provides support and retention, transfer of load, reinforcement of the connection, and cosmetic protection during the joining process. Choosing the right rivet head ensures a quality, reliable and durable connection.

There are three general head shapes for blind rivets: countersunk head, round head and large flange head. In most cases, round head blind rivets will fulfill the requirements of the application. Large flange head blind rivets are used where greater support and load carrying capacity is required. And countersunk head blind rivets are suitable for applications that require a flat, bump-free joint surface. When selecting a head type, it is important to consider the requirements of the connection, the nature of the material, and the desired support and appearance.

Differences in Blind Rivet Threads

Blind Rivets have different threads depending on the application. The internal threads of a blind rivet are usually located at the bottom of the rivet. It can accept threaded bolts or nuts for a stronger connection. Internally threaded blind rivets are typically used in applications that require a removable connection.

The external threads are usually located on the top of the rivet. Capable of accepting nuts or other threaded connectors for a stronger connection. Externally threaded blind rivets are typically used in applications where additional holding force is required during the joining process or where they need to be used in conjunction with other threaded connectors.

Grip Range of Blind Rivets

The grip range of a blind rivet is the range of thicknesses of plates or connections it can join. It indicates the distance between the minimum and maximum thickness of the material that a blind rivet can grip.

The grip range is an important parameter. If the grip range of a blind rivet exceeds the thickness range of the material to be joined, the connection may fail or not achieve the required strength and reliability.

Typically, the length of the blind rivet and the core length (the length of the blind rivet sticking out of the sheet) affects the range of its grip range.

When selecting a blind rivet, it is necessary to determine the appropriate grip range of the blind rivet based on the thickness of the material to be joined.

How do I Know My Rivet Size ?

Blind Rivets are typically sized by diameter, length and core length. When approaching the blind rivet business, you will often see numbers such as 1/8″, 1/4″, etc., which represent the diameter of the blind rivet. Take a 1/8″ (0.125 inch) blind rivet as an example to explain how to determine the size of a blind rivet:

Diameter: The diameter of a blind rivet is usually expressed in inches or millimeters. 1/8″ blind rivets, indicates a diameter of 1/8″ or 3.175 mm.

The conversion of inches to millimeters can be done very simply by following the formula. (mm = in/0.039370)

A complete description of a rivet requires knowing its rivet body length in addition to its diameter. A 3.0 x 6.0 is used as an example for illustration.3.0 means the diameter of the blind rivet is 3.0mm, or 7/61″ inch. 6.0 means Body Length is 6.0-7.0mm length.

With the above information, you will have a complete representation of the size of the rivets.

Rivet Hole Size Chart

To achieve a tight joint, in addition to the rivet size selection being important, the rivet hole is also critical. After determining the rivet size, the hole size must be marked for drilling. Generally, the diameter of the rivet needs to be slightly smaller than the diameter of the hole. This allows the rivet to be inserted without any obstacles, maximizing the gap filling and achieving a tight connection.

Rivet Size and Drill Size

| Rivet Diameter | Hole Diameter Size | |

| Min | Max | |

| 2.4(3/32") | 2.5 | 2.6 |

| 3.0(7/61") | 3.1 | 3.2 |

| 3.2(1/8") | 3.3 | 3.4 |

| 4.0(5/32") | 4.1 | 4.2 |

| 4.8(3/16") | 4.9 | 5.0 |

| 5.0(6/32") | 5.1 | 5.2 |

| 6.0(15/64") | 6.1 | 6.2 |

| 6.4(1/4") | 6.5 | 6.6 |

Notes on Measuring Blind Rivets

There are several considerations when making blind rivet measurements:

- Use the correct measuring tools and techniques. Ensure that the tools used are accurate and reliable, and that the proper measurement methods are used to obtain accurate measurements.

- Ensure accuracy and consistency of measurements. Before each measurement, check the accuracy of the measuring tool and maintain a consistent method and force when performing the measurement.

- For complex blind rivets, special measurement methods and tools may be required. In this case, ensure that you have a detailed understanding of the measurement requirements for the particular blind rivet and select the appropriate tool and method for the measurement.

Conclusion

Correctly measuring blind rivets is a critical step in keeping your project safe. Hopefully, with the comprehensive guide provided in this article, you will learn how to properly measure blind rivets for diameter, length, head shape and thread type. Of course you can, using the correct tools is also an important part of the process. Maintaining accuracy and consistency in your measurements is quite important.

Whether you are a distributor of blind rivets or a project owner, being able to accurately measure blind rivets is a critical step in ensuring safety and reliability when selecting connecting fasteners. By following the guidelines provided in this article, you can select the blind rivets that best suit your needs and make accurate and safe connections.

Rivamte can Provide Blind Rivet Solutions for you

Rivmate is the top Blind Rivet manufacturer in China. Whether you are a business owner or a purchasing manager, you can wholesale a large selection of high quality and affordable blind rivets from Rivmate.

Rivmate is committed to providing professional blind rivet solutions to fastener companies worldwide. You can solve all your blind rivet sourcing needs at once at Rivmate.

For wholesale bulk blind rivets, choose Rivamte Rivet.

Submit Your Sourcing Request

Please complete the form below and our customer support team will be in touch with you shortly. Inquiries submitted through this form will receive priority processing over emails.