Table of Contents

Rivets vs Bolts ! Do you have questions about whether to use bolts or rivets? Don’t worry, this article will provide you with the most comprehensive comparison guide!

Table of Contents

What are Bolts

A bolt is an external helical threaded fastener often used to fasten objects with threaded holes together. Bolts have a threaded, cylindrical body and a bolt head at the top. Bolts are often used in conjunction with nuts or threaded holes and are torqued to create a solid connection.

Bolts are used in a wide variety of applications, including construction, automotive manufacturing, machine building, aerospace, and more. Different applications require different types and sizes of bolts. For example, bolts used in automotive manufacturing typically need to be high strength and vibration resistant, while in construction, bolts may need to be corrosion resistant and wind load resistant.

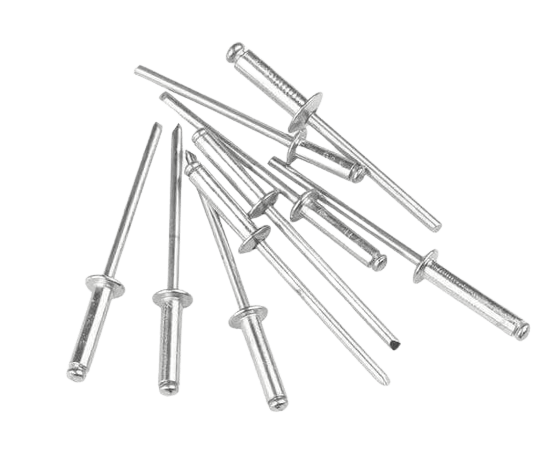

What are Rivets

Rivets are also a commonly used mechanical fastener. It is usually used to create a stable connection between thin plates. In practical engineering applications, rivets are an optimal alternative solution to welding and gluing.

The economic cost of rivets is relatively low and the installation can be done easily. An untrained engineer can complete the installation process using special installation tools. Because of this feature, rivets are preferred by most manufacturers.

Rivets offer a number of advantages, such as their ability to be used in situations where fastening from either side is not possible, providing a reliable connection, as well as high shear and tensile strength. They are suitable for a variety of applications including automotive manufacturing, aerospace, construction and metal structures.

What are the Most Common Types of Rivets and Rivet Tools?

One of the most cost-effective fasteners for riveted parts, rivets are available in a wide variety of types. No matter what the project, there will be a rivet that will meet the requirements of your project. Of course, cost, strength requirements and size are the primary considerations when selecting a rivet.

Common types of rivets include solid rivets, blind rivets, high strength structural rivets, hollow rivets and SPR rivets. We can provide you with many different types of rivets and corresponding riveting tools. We can meet the requirements of different projects.

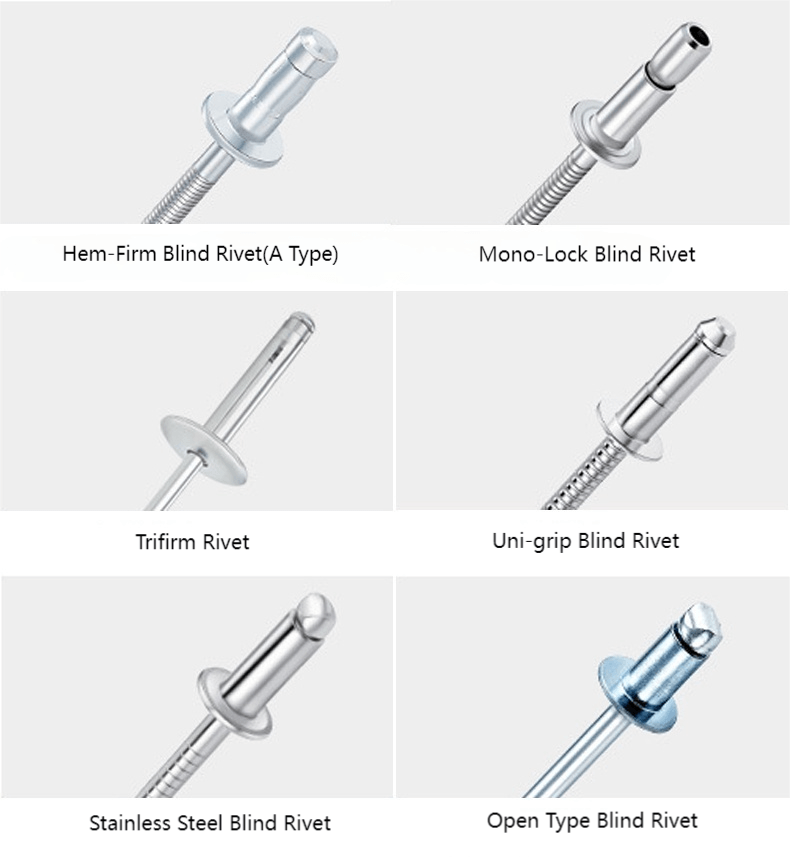

Blind Rivet

Blind Rivet is also called Pop Rivet. blind rivet can be used in some regular riveting scenarios. blind rivet is ideal in scenarios where space is limited and access to the back of the material is not possible. Blind rivets are ideal for applications where space is limited and access to the back of the material is not possible, as they require only one side to complete the riveting process.

Common types of blind rivets are the open type blind rivet and the sealed type blind rivet, which are the original types of blind rivets for applications that do not require a high degree of strength. These two types of blind rivets are the original types of blind rivets for applications that do not require a high degree of strength, including non-load bearing sheet metal connections or component connections.

Their prices are very low and you can use them if your project requires average strength.Blind rivet will leave you with a big financial cost!

Structural Rivet

As the world’s technology advances and develops, the traditional Blind Rivet is no longer able to fully meet the requirements of industrial manufacturing, Blind Rivet is not able to meet some high-intensity application scenarios. So high strength structural blind rivets have been invented.

As we all know, in order to meet the development of industry, the types of blind rivet are very many. The most common Multi grip blind rivet, monbolt rivet, waterproof bulb tite rivet are some types of high strength structural rivets.

Solid Rivet

Solid rivets are also a common type of rivet. It is made from a complete piece of metal material. Solid rivets have superb strength and better durability. Of course, if your solid rivets are made of stainless steel or aluminium, they will also have good corrosion resistance. There is no way to remove a solid rivet once it has been installed, so the connection it provides is permanent and the strength of the joint is very reliable.

In addition to this, the installation of solid rivets is also very complex. It requires the use of a hammer or a pneumatic riveting machine to complete the installation.

Due to the extra strength and stable connection of solid rivets, they are often used in some heavy duty industries. This includes the installation of components for metal structures, bridges, buildings and ships. Solid rivets also play an important role in automotive manufacturing and aerospace, where they are commonly used to secure body structures, chassis components and suspension systems.

SPR Rivet

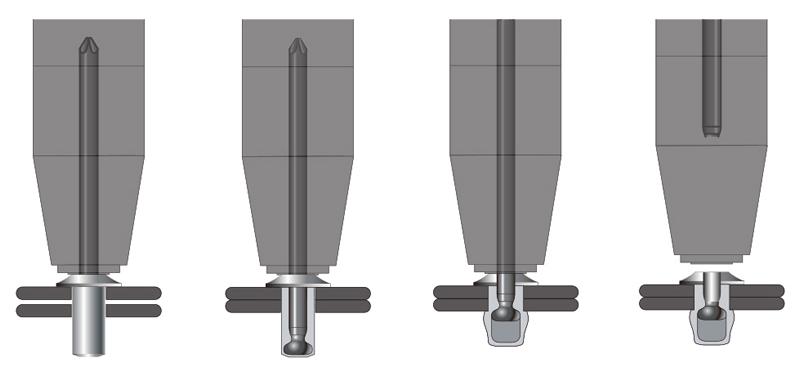

SPR Rivet stands for Self Piercing Rivet. It is a special type of rivet especially suited for joining thin sheets of metal.SPR rivets are used to form a strong joint by forming a hole in one side of the workpiece and then passing the rivet through this hole and pressing it together.

There are many advantages of SPR rivets, including but not limited to :

- The ability to quickly automate installation, greatly increasing productivity and connection speed.

- SPR rivets do not require pre-drilling, and it’s a gentle piercing process that avoids damage and deformation of materials.

- SPR rivets do not require additional welding or gluing treatment after connection, reducing the subsequent processing procedures.

Of course SPR rivets have some disadvantages:

- 1.SPR rivets usually require specialised equipment and tools for installation, which may increase some equipment investment costs.

- 2.The installation of SPR rivets requires training and expertise to ensure a proper installation process and connection quality.

The application scenarios of SPR rivets are also very many.

- SPR rivets are widely used in automotive manufacturing to connect body structures, doors, roofs and other components.

- SPR rivets have high strength and lightweight characteristics, they are used in the aerospace field to connect aircraft structures and spacecraft components.

- SPR rivets are used to join components such as housings, heat sinks and internal structures of appliances and electronic equipment.

- SPR rivets are also used to join structures and components of railway vehicles, ships and other vehicles.

It is important to note that the use of SPR rivets should be evaluated based on specific needs and application scenarios to ensure proper selection and installation for reliable connections and efficient production processes.

Riveting Tool

If you want to finish the installation of rivets well, then you can’t do it without the help of a rivet gun.

There are three types of rivet guns in general:

- manual riveting tools

- electric rivet guns

- pneumatic rivet guns.

If you are for personal use and need to rivet very few rivets, then you can choose the cheapest manual rivet tool. If you need to use it in industry, then I suggest you to choose pneumatic rivet gun, then you can finish the riveting process quickly.

What Are the Disadvantages of Rivets?

Rivets are one of the most commonly used fasteners, but they still have some drawbacks.

- Non-removability: Once installed, rivets usually cannot be removed. If a connection needs to be undone or a part needs to be repaired or replaced, the rivet needs to be cut or drilled, resulting in additional work and material loss.

- Limited Adjustability: The position or tightening force of a riveted connection is often not easily adjustable. Once installed, adjusting the position or tightening force of the connection can be very difficult, which may be limited in some applications.

- Installation Complexity: Rivets can be more complex to install than bolts. Installation of rivets often requires special tools and equipment, such as rivet guns or riveting machines, as well as skilled handling.

- Risk of loosening due to vibration: In environments with frequent vibration or shock, rivets may lose their tightening force due to loosening. This may require regular inspection and maintenance to ensure the reliability of the connection.

- Limitations to materials and thickness: Rivets are suitable for joining metallic workpieces, but may be less suitable for joining non-metallic materials or very thin materials. This may require consideration of alternative joining methods or the use of specially designed rivets.

What is the Difference Between Riveting and Bolting?

Riveting connections and bolting connections are two common methods of mechanical connections. But there is still a big difference between them. Mainly in the working principle, removability, adjustability, installation complexity and applicable materials and thickness.

Working Principle:

- Riveted Joining: Riveting is the use of deformation to form a strong joint by driving a rivet through a workpiece and pressing it together. This usually involves forming a hole in the workpiece on one side and using a rivet gun or similar tool to compress the head of the rivet on the other side, creating a diffuse deformation that holds the workpieces together securely.

- Bolted Joining: Bolted joints are made by passing a bolt through a workpiece and clamping two or more workpieces together using a nut. The threads between the bolt and the nut provide the tightening force that holds the workpieces together.

Disassemblability:

- Riveted Connection: Riveted connections are usually not removable. Once the rivets are installed, it is usually necessary to cut or drill holes to undo the connection.

- Bolted Connections: Bolted connections are removable and can be unlocked by loosening the nut, allowing for easy access for repairs, replacement of parts, or adjustments.

Adjustability:

- Riveted Connection: The position or tightening force of a riveted connection cannot usually be adjusted. Once installation is complete, adjusting the position or tightening force of the connection may be very difficult.

- Bolted Connections: bolted connections allow the tightening force of the connection to be adjusted by loosening or tightening the nut, making adjustment of position and tightening force more flexible.

Installation Complexity:

- Riveted Connections: riveted connections are relatively more complex to install and usually require specialised tools and equipment, such as rivet guns or riveting machines, as well as skilled operating techniques.

- Bolted Connections: Bolted connections are relatively simple to install and usually require only basic tools such as bolts, nuts and spanners, which are easier to carry out.

Applicable Materials and Thickness:

- Riveted Joints: riveted joints are suitable for joining metal workpieces, but may be less suitable for joining non-metallic materials or very thin materials.

- Bolt Connection: bolt connection is suitable for connecting various materials, including metal, plastic, etc., and also has good adaptability for workpieces of different thicknesses.

Are Rivets Better than Bolts in Your Joint Assembly?

There’s a great saying — “There is no such thing as the best fastener, only the best fastener for the job.” So there is no way to make a blanket statement that rivets are better or worse than bolts in connecting fasteners.

If you have to say whether rivets are better or bolts are better, you have to think about the question from more than one angle. The choice of rivets or bolts depends on the specific needs and conditions of the application. If a high-strength, non-removable joint is required, rivets may be more appropriate. If disassembly, adjustability and flexibility are required, bolted connections may be more appropriate. The best choice should be based on a thorough evaluation and weighing of the connection requirements.

Why Use Rivets Instead of Bolts

Compared to bolts, rivets are typically more resistant to vibration, which makes them the best choice for applications where severe vibrations often occur.

High-strength structural rivets are more suitable than bolts when your project requires a high-strength connection and a product that is less prone to loosening. While bolts can provide a high level of strength, they are prone to loosening in environments with frequent vibration or shock.

If your project has a lightweight requirement, bolts are obviously not suitable. Rivets are much lighter and can reduce the weight of the connected parts. Rivets can provide a more lightweight solution.

Rivets can be installed much faster than bolts. Rivets are usually more resistant to vibration, which makes them the best choice for applications where severe vibration often occurs.

In addition to this, rivets can often be installed quickly, which is particularly useful when large numbers of these fasteners need to be installed into industrial machinery, making them a more economical choice.

One of the most significant advantages of choosing rivets is their ability to be installed into blind holes. Unlike threaded fasteners, blind rivets do not need to touch the other side of the fastening surface to be installed and form a strong bond.

Rivets are also relatively lightweight, further encouraging their use in weight-critical applications where they are able to fasten thin plates without distortion from welding.

Industrial applications that benefit from these advantages include the assembly of aircraft skins and military equipment.

When to Use Rivets Instead of Bolts

Want to know when rivets can replace bolts? Actually, if you’re in the industrial manufacturing field, then you’ve already seen them on heavy structures like bridges, skyscrapers and ships. Ever since they were invented, rivets have been the fastener of choice due to their strong connection and durability. Of course, high-strength bolts have advanced, but their high cost has prevented them from being used on a wide scale.

In today’s quest for quality and lightness, rivets have been used instead of bolts in aerospace and automotive manufacturing. Rivets can perform basically all the functions that bolts can perform, but they introduce overall weight. Rivets can provide a complete lightweighting solution.

Rivets have also replaced the dominance of bolts in the field of construction and structural engineering. This includes joining steel structures, bridges, stairs, platforms and industrial equipment. The reliable strength and stability provided by rivets are adapted to the high load and vibration environments of large structures.

Rivmate can Help You with Your Riveting Needs!

Want to purchase rivets? Send inquiries to top China Rivet manufacturers now!

You can get all types of rivets from Rivmate, whether they are standard rivets or high strength structural rivets. You can find satisfaction with all of them here.

What are you waiting for? Solve all your rivet sourcing needs at once! Contact us now!

Reply within 12 Hours

Send us a message if you have any questions or request a quote. We will be back to you ASAP!

Location

+86 189 6230 4392

or write

manufacture@world-rivet.com