Monobolt vs Pop Rivet - The Most Complete Buyer's Guide

Monobolt Rivet and Pop Rivet are two types of rivets that are widely used in the field of joining and fastening. But there are many people who don’t know the difference between these two types of rivets for their projects. Therefore, understanding the basics of rivets can help you make an informed decision when choosing the right rivet for your needs. Let’s get started!

Table of Contents

What is A Monobolt?

Monobolt rivet is a type of structural blind rivet. But it has been modified from the traditional rivet.

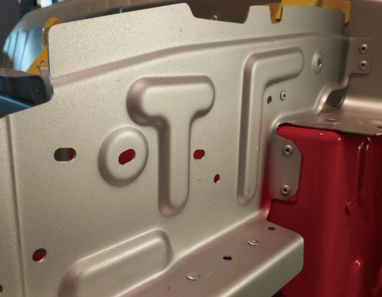

The main feature of Monobolt rivet is the locking bar construction. That is, in its riveting process, there is not only the process of the top bar expanding the nail body to fill the hole, there will be a mechanical locking step. This locking structure is visible to the naked eye.

Monobolt rivet can provide very strong tensile and shear forces. And there are several material combinations to choose from.

Advantages of Monobolt Rivet

Monobolt rivets are the most widely used high strength structural blind rivets. monobolt rivets offer several advantages, so monobolt rivets are often found in a variety of heavy-duty applications.

- High shear and tensile strength

- Visible external locking structure

- Excellent hole filling properties

- Large riveting grip range

- Mechanical mandrel locking mechanism which avoids damage,electric leakage or marowak sound caused by the loosening of mandrel

Disadvantages of Monobolt Rivet

Monobolt rivets are not without their drawbacks.Monobolt rivet is relatively costly due to its special construction and manufacturing process. And when installing Monobolt rivets, you need to use special tools and equipment, which may increase the threshold of use and cost.

Where to Use Monobolt Rivet?

Monobolt rivet makes a very stable connection in automotive manufacturing, aerospace and construction. You can use them to secure the connections of your project and in doing so, set your business up for success.

If your application requires high strength and vibration resistance, then Monobolt rivet can provide you with a reliable connection solution. Clearly, Monobolt rivets are an ideal choice for these important scenarios.

What is a Pop Rivet?

Pop rivet and blind rivet refer to the same type of rivet. As the materials used to build airplanes shifted from wood and metal to all-metal, fasteners that allowed for one-sided connections became important.The pop rivet was invented by Hamilton N. Wylie in England.

In the 1920s, Wylie went to work for the Armstrong-Whitworth Aircraft Company and later helped further develop the pop rivet with the Tucker Eyelet Company. Together, the two companies created a rivet design.

The new fastener was called a pop rivet because the new rivet’s mandrel head popped out after the rivet was installed and the mandrel head made a popping sound when it broke.

What is the Advantage of Pop Rivet?

Pop rivet is used in many industrial and furniture building projects. Let’s discuss their benefits and applications.

Quick Installation

Pop Rivet is a relatively simple installation process, usually requiring only the insertion of rivets and the use of specialized tools to secure them. Compared to other joining methods such as bolts and nuts, Pop Rivet can be installed much faster, saving significant time and labor costs.

Affordable

Pop Rivet is generally more economical than other joining methods. Its relatively low cost makes it suitable for mass production and high volume use. In addition, no expensive equipment or tools are required to install Pop Rivet, further reducing the cost of ownership.

Reliability

As long as you are installing Pop Rivet correctly, then it provides reliable connection strength. The chip formed by the deformation of the rivet shell holds the workpiece tightly, ensuring a strong and vibration-resistant connection. This makes Pop Rivet suitable for many applications, including aerospace, automotive manufacturing, construction and furniture manufacturing.

Special Features

There are many types of Pop Rivet. Different types of pop rivet have different functions. , such as closed type blind rivets, have better waterproofing properties. When installed on sealed materials, these rivets are effective in preventing water or other liquids from penetrating the joint, providing additional protection.

What is the Disadvantage of Pop Rivet?

- Compared to welded or bolted connections, Pop Rivet has a lower connection strength.

- Once Pop Rivet is installed, its connection is irreversible.

- Prior to installing Pop Rivet, holes need to be pre-drilled to match the rivet diameter.

The Best Strategy for Pop Rivet

Do some brainstorming before deciding on the connection effect you want to achieve with pop rivet.

Analyze the Nature of the project

In order to achieve a perfect riveted joint, the engineer must first understand how the project will be used. He must determine where the pop rivet will be attached, what part of the part will be attached, and how much strength is needed. Typically before purchasing pop rivet in bulk, you need to figure out the following factors: 1. the type of material being joined 2. the loading requirements of the project 3. the environmental conditions in which the application will take place

When to Use Pop Rivet ?

You need to always keep in mind that you can’t use pop rivet in application areas that are subjected to extra strength (e.g., load bearing bridges, automotive crash cushions, cranes, etc.) Such extra-heavy duty applications require the use of higher strength bolt type rivets.

In scenarios where a lightweight design is required, the pop rivet is the primary choice. Such applications include the assembly of automotive parts, aerospace equipment, marine parts, and more.

Monobolt vs Pop Rivet

There are some differences between Monobolt rivet and pop rivet. But essentially, they are both the same type of product. Each of these rivet has its own importance and application. No one rivet is better than the other. Depending on the needs of your project, it makes sense to choose between a high-strength rivet like the monobolt rivet or a regular rivet like the pop rivet.

In practice, however, a project will generally not use only one type of rivet. For a more economical project, you will need a perfect pop rivet solution.

For connections that need to carry a lot of weight, you can use a monobolt rivet. for other general parts, you can just use a pop rivet to complete the connection.

Final Words

This article explains the importance of monobolt rivet and pop rivet and where to use them in your project.

Rivmate rivet has been successfully China’s top pop rivet solution manufacturer and provider. For all your sourcing needs regarding monobolt rivet and pop rivet, you can contact us for advice, consultation or quotation. We look forward to helping you take your business to the next level.