Grip Range for Rivets - The Guide to Choosing Right Grip Range

As an important member of fasteners, blind rivets are widely used for their fast and stable characteristics. The riveting range is an important parameter of blind rivets, which determines whether the riveting effect is stable or not. This article will bring you an in-depth understanding of the grip range for rivets.

Table of Contents

What is a Blind Rivet ?

The Blind Rivet is a common type of rivet used in a wide range of industries and fields. Its structure and working principle make it a reliable joining solution.

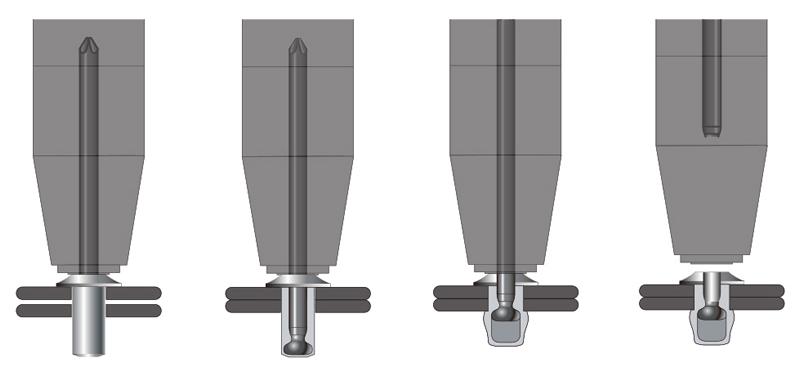

Using a blind rivet is also very simple. Simply pre-drill holes in the material to be joined. Then, the rivet body is inserted into the hole, making sure that the open portion is on one side of the material. Subsequently, by using a rivet gun. the mandrel is pulled through the rivet body until the head of the mandrel is completely inside the rivet body. During this process, the rivet body expands and clamps down on the connected material, forming a strong connection. Finally, the mandrel head is broken off so that its remaining portion is flush with the rivet body.

Blind rivets have many applications. Including automotive manufacturing, aerospace, construction and manufacturing. Some of their common applications include body assembly, aircraft construction, building bridges, electronic equipment and furniture manufacturing. Due to the design and working principle of blind rivets, they are able to provide great shear and tensile strength and are suitable for applications where high strength connections are required.

Construction of Blind Rivets

A Blind Rivet consists of three main components: the body of the rivet, the mandrel and the mandrel head. The body of the rivet is usually a hollow cylindrical structure with an opening at each end and a closed head. The mandrel is a needle-like bar that passes through the body of the rivet, while the mandrel head is located on one side of the mandrel.

What is Grip Range for Rivets?

Grip range is the range of material thicknesses to which a blind rivet can be adapted. In a blind rivet connection, the grip range is the distance between the minimum and maximum dimensions of the material thickness that the rivet can fasten.

The role of grip range is very important for blind rivets, especially in blind rivet connections. It determines the range of material thicknesses that the rivet can accommodate, ensuring the reliability and strength of the connection. If the clamping range is too small, the rivet may not be able to clamp the material, resulting in a loose connection. If the clamping range is too large, the rivet may not be able to provide sufficient tightening force, resulting in a weak connection or failure to achieve the required strength.

Therefore, accurate selection of the proper blind rivet clamping range is critical to ensuring the reliability and safety of the connection. When selecting a blind rivet, it is important to take accurate measurements of the thickness range of the material and select a rivet with a clamping range that completely covers that range.

How to Choose the Right Grip Range for Rivets ?

- Measure the thickness of the material to be riveted: Use a suitable measuring tool to accurately measure the thickness of the material to be joined. Ensure that the material is in a flat state when measuring to obtain an accurate thickness value.

- Determine the range to be gripped: Once the thickness of the material is known, the range to be gripped can be determined based on the specifications of the blind rivet and the clamping range information provided by the manufacturer. Clamping ranges are typically expressed as upper and lower limits of minimum and maximum material thickness.

- Selecting the appropriate gripping range: Select a gripping range that completely covers the range of thicknesses of the materials to be joined.

- Consult the manufacturer or supplier: If in doubt, contact the manufacturer or supplier of the blind rivet for more detailed clamping range information and recommendations.

- Conduct trials and sample tests: Before proceeding with large-scale riveting, it is recommended to conduct trials and sample tests. Select a few representative material thicknesses and test them with blind rivets of different clamping ranges. By checking the tightening force and stability of the connection, the riveting range best suited to the actual application can be determined.

- Be aware of special requirements: Some applications may require special riveting ranges. For example, for thinner materials, it may be necessary to select rivets with a smaller clamping range to avoid over-clamping that could result in deformation or rupture of the material. In this case, more accurate measurement and selection of the clamping range is particularly important.

You can rest assured. When you follow the above steps for the riveting range of blind rivets, you can get the blind rivets that best fit your project.

Relationship Between Grip Range for Rivets and Joint Strength

The proper Grip range ensures a safe and reliable connection. too small or too large a Grip range of a blind rivet can result in a weak or unreliable connection.

Grip Range is Too Small

If the Grip range is too small, the rivet cannot clamp the material. In this case, the connection may loosen because the rivet cannot provide sufficient tightening force. The material may be displaced relative to each other when subjected to external forces or vibrations, resulting in failure of the connection. Additionally, a Grip range that is too small may result in stress concentrations, leaving the material susceptible to rupture or damage.

Grip Range is Too Large

If the Grip range is too large, the rivet may not provide sufficient tightening force, resulting in a weak connection or failure to achieve the required strength. In this case, the connection may become loose or deformed, reducing the strength and reliability of the connection.

Conclusion

Therefore, selecting the proper Grip range is critical to ensuring the safety and reliability of the connection. The right Grip range allows the rivet to properly clamp the material, providing sufficient tightening force to resist external forces and vibration. This ensures a solid connection and provides sufficient strength to meet the requirements of the application.

So in order to select the proper Grip range for rivets, it is important to accurately measure the thickness of the material and refer to the Grip range information provided by the Blind Rivet manufacturer. Ensure that the selected clamping range will completely cover the thickness range of the material and allow for an appropriate margin. If in any doubt, it is recommended to consult the manufacturer or supplier for professional advice.

Potential Problems and Solutions Due to Grip Range Errors

Loose Connection

Rivets with too small a Grip range are unable to clamp the material, resulting in a loose connection. This may reduce the strength and reliability of the connection.

Response Measures:Correctly measure the thickness of the material and select a rivet with a clamping range that completely covers the thickness of the material. If the clamping range is small, consider selecting a rivet with a larger clamping range.

Connection Failure

If the grip range selected is too large, the rivet will not provide sufficient tightening force, resulting in failure of the connection. The connection may loosen, distort or fail to achieve the required strength.

Response Measures: Consider selecting rivets with a smaller grip range

Stress Concentration

Grip ranges that are too small may cause stresses to concentrate in localized areas, increasing the stress on the material and increasing the risk of rupture.

Response Measures: Ensure that the appropriate grip range is selected and do not select a range that is too small. Try to select rivets with a grip range that matches the thickness of the material to evenly distribute the stresses of the connection

Unstable Connection

If the grip range is not selected properly, the connection may become unstable. This may result in wobbling, loosening or deformation of the connection, affecting the reliability and stability of the connection.

Response Measures: Ensure that the clamping range selected provides proper stability and tightening force. Refer to the clamping range information provided by the Blind Rivet manufacturer and select the appropriate rivet for the specific application.

Looking for Blind Rivet Manufacturer? Rivmate can Help you !

Want to wholesale imported blind rivets and rivet nuts in bulk? Looking for reliable Blind Rivets and Rivet Nuts manufacturers? Don’t worry, Rivmate can provide you all types of blind rivets and rivet nuts.

For half or even a third of your local price, you can get the same quality rivet fasteners.Contact us today to buy Blind Rivets in bulk!