Table of Contents

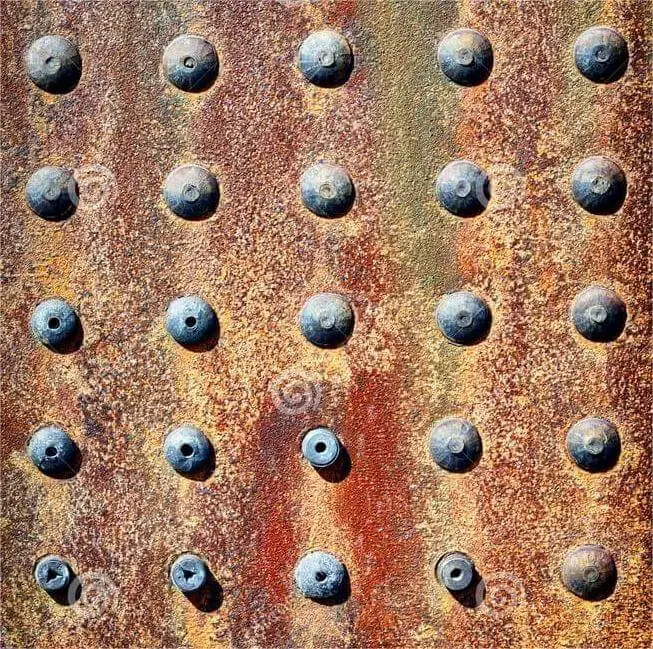

Do Rivets Rust? I’m sure we’ve all encountered rusty rivets in practical applications. So do you know why rivets rust? In the end, how should we prevent rivets from rusting? Through this article, you will understand these questions clearly!

Table of Contents

Why Do Blind Rivets Rust?

When you work with metal products, it’s inevitable that you need to consider the rusting of blind rivets. Rusting of blind rivets refers to the phenomenon that the surface of blind rivets undergoes an oxidising reaction and rust is formed.

If your project is one that needs to be in a wet environment for a long period of time, then rust can easily develop. This can reduce the corrosion resistance, strength and joining properties of a blind rivet.

That’s why it’s important to prevent rust. Rusting can be minimised by using appropriate materials, surface treatments, protective measures or regular maintenance.

Will a Steel Rivet Rust ?

Obvious. Steel rivets do rust. When rivets are exposed to moisture and oxygen, an oxidising reaction occurs and rust forms.

To prevent steel rivets from rusting, there are often protective measures taken. For example, coatings or surface treatments are applied to separate the surface from moisture and oxygen. Of course, if you can go for regular inspection and maintenance, this can detect the problem and deal with the rust in time, which can prolong the service life and performance of steel rivets.

Will Stainless Steel Rivet Rust?

Normally, stainless steel rivets will not rust. Stainless steel rivets have better rust resistance because a certain amount of chromium is added to stainless steel, forming a dense layer of chromium oxide. This chromium oxide layer provides a certain degree of corrosion protection, is stainless steel has a high resistance to rust.

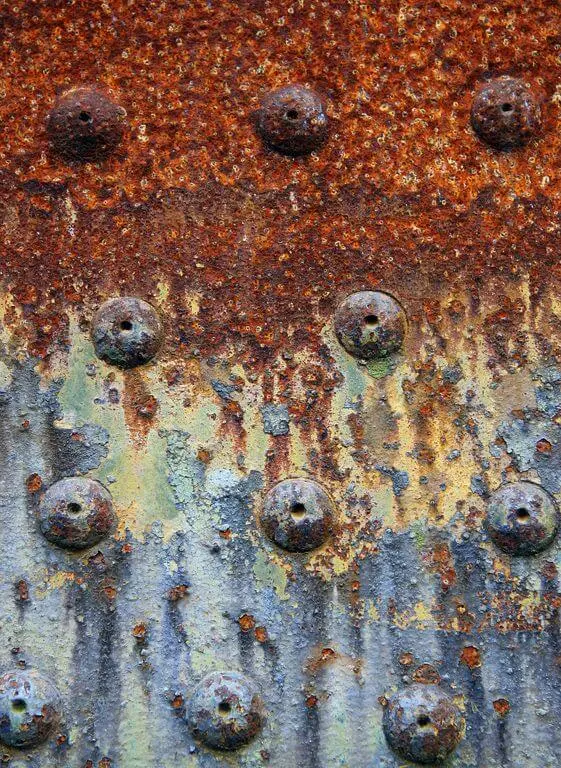

But stainless steel rivets are not absolutely will not rust. For example, in the strong acid, strong alkali environment, high salinity environment or line time exposure in the humidity thereafter, stainless steel rivets may still occur rust phenomenon.

In addition, if the surface of the stainless steel rivets are damaged, scratched or subjected to chemical corrosion, may also lead to its rust. Therefore, even with the use of stainless steel rivets, they still require proper maintenance and protection to ensure their resistance to rust. Regular cleaning, avoiding contact with corrosive substances and taking appropriate protective measures can all help to extend the life of stainless steel rivets and reduce the risk of rusting.

What metal is completely rust proof?

The truth is that no metal is completely rust-proof. All metals have the potential to rust under the right conditions.

However, certain metals are highly resistant to rust because of their chemical properties and special surface treatments. Common metals are stainless steel, aluminium and copper. Their resistance to rust, in descending order, is stainless steel > aluminium > copper.

How to Remove Rust From Rivets

In daily engineering use, want to remove the rust on the blind rivets, the current method is divided into two main categories: physical removal and chemical removal. Next I will explain in detail the various methods of removing rust.

Mechanical Removal

If there are not many rusted rivets, you can use some items with high friction, such as wire brushes, sandpaper, grinding wheels and other tools to scrub or sand the surface of the rivets to remove the rust. This method is suitable for light rusting situations.

Chemical Removal

Rust can be effectively removed from rivets using chemical solutions or rust removers. Common rust removers include acid solutions, acid cleaners, and acid sprays. When using chemical rust removers, follow product instructions and use them safely.

Electrolytic Rust Removal

Electrolytic rust removal is a method of removing rust through an electrochemical reaction. The rivet is used as the cathode and is immersed in an electrolyte with an anode (such as an iron plate), which causes the rust to come off the surface of the rivet by the action of an electric current. This method is suitable for more serious rust cases.

Anti Rust Coatings

After the rust has been removed, an anti-rust coating such as anti-rust paint, coating or coating can be applied in order to prevent re-rusting. These coatings provide protection against re-rusting of rivets. The cost of maintenance is reduced.

How to Prevent Rivets from Rusting?

In order to avoid losses due to the rusting of rivets, in practice, engineers use a variety of methods to prevent the rusting of rivets. Next, I will list the common rust prevention measures.

Choose Materials that Resist Rust

You’ve got to have a business that requires high levels of rust resistance, so when choosing raw materials at the outset, choose materials with good corrosion resistance, such as stainless steel (especially 316 stainless steel), galvanised steel, and so on. Rust-resistant materials can isolate a lot of rusting situations, and even if rusting occurs because of harsh environments, the process will be prolonged for a long time. These materials provide better resistance to rust and reduce the risk of rivets rusting.

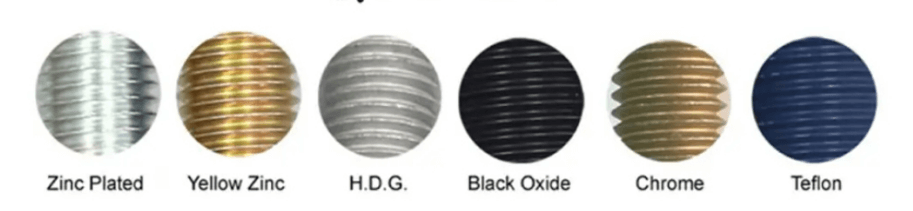

Surface Treatment

To achieve a good anti-rust effect, in addition to selecting rust-resistant performance strength raw materials. You can also carry out surface treatment of rivets, such as galvanising, electroplating, spraying anti-rust coatings, etc., to form a layer of protection, isolate the contact of oxygen and moisture, reduce the possibility of rust.

Protective Measures

If you have a project that requires a particularly high level of rust prevention, in addition to the above two measures, you can also take additional protective measures on rivets that are exposed to humid environments. For example, use waterproof tape, waterproof paint, protective sleeves, etc., so that you can effectively isolate the rivets from contact with moisture.

Regular Maintenance

In addition to preparing in advance to prevent rust, it is also important to check the condition of the rivets regularly while the project is already in operation. Any signs of rust can be detected and dealt with in a timely manner. Cleaning the surface of the rivets of dust and dirt and avoiding the accumulation of moisture will help to prevent rust and corrosion.

Use the Right Sealing Material

In applications where sealing is required, ensure that the selection of a suitable sealing material is effective in preventing moisture from penetrating the contact surface around the rivet. For example, use closed rivets to complete the joints on your project.

Conclusion

A focus on rivet performance signals not only a commitment to environmental stewardship, but also a strategic move toward high-quality project planning on your part. Focusing on rivet performance means reducing maintenance costs, improving project safety and minimising losses due to rivet rust.

Although the cost of specially treated rivets may be slightly higher, it highlights the importance of being responsible for the safety of your project and valuing your business.

Maintenance costs, particularly for blind rivets, are heavily influenced by the raw materials and protective measures used up front. In addition, the right blind rivets can deliver even greater benefits! Not just financial benefits, but more benefits for your brand!

Rust Prevention with Rivmate Rivet

As we enter an era where sustainable and high quality riveting systems are vital, Rivamte Rivet is at the forefront, offering customised solutions. Supplying high quality rivets and rivet nuts.

Our commitment to pioneering environmentally friendly and cost saving customised riveting solutions is commendable and we invite you to join us in our journey towards a safer, more sustainable future.

Discover Rivmate Rivet: get an insight into our rivet range and our requirements for high quality rivets! Contact us today!