Closed End Rivet.How to Choose the Right Rivet for Your Project ?

Closed end rivets: A sealed fastener that is widely used in various industries. Is one of the core products of the popular riveting expert website, we provide customers with different types of sealed rivets. If you are looking for the right seal rivets for your project, this article will provide you with some useful information and advice.

Table of Contents

What is a closed end rivet?

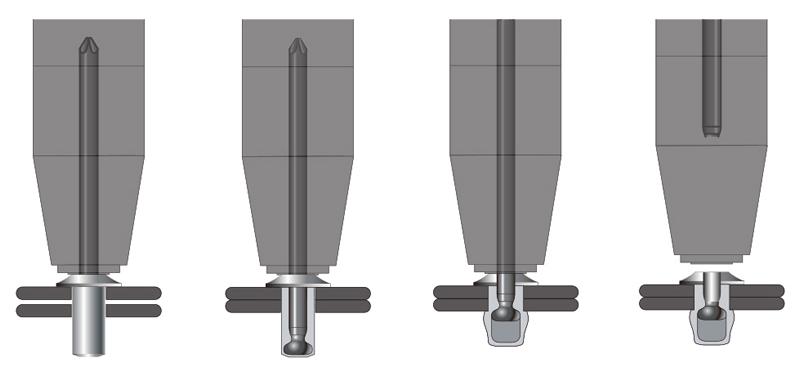

A closed rivet is a fastener with a port seal designed to provide strong connectivity and air tightness. The closed end rivet is composed of a rivet body, a rivet cover and a rivet core. The rivet body and cover can be made of high-performance carbon steel, stainless steel, or aluminum, while the rivet core is usually made of copper or aluminum.

.png)

How does a closed end rivet work?

Closed rivet works similar to traditional rivet. They achieve connectivity by inserting one end of the rivet into the part and riveting the other end together using a rivet gun or other tool. However, closed end rivets have a port seal that provides better connectivity and air tightness than conventional rivets.

When installing closed rivets, here are some common steps:

Preparation: Select the appropriate rivet gun and rivet head and check that it fits the required size and type of rivet. In addition, check that the number of rivets and materials required are correct.

Pretreatment: Before installing closed rivets, ensure that the surface of the part is clean and smooth to ensure the correct installation of the rivets.

Drilling: Drill holes in the part, ensuring that the diameter and depth of the holes are suitable for the required rivet size. Use tape or other protective material in the area around the hole to prevent damage to the surface from the rivet gun.

Install the rivet: Insert one end of the rivet into the hole and use a rivet gun or other tool to rivet the other end together. Before inserting one end of the rivet into the hole, ensure that the end cover of the rivet has been completely removed to ensure the correct installation of the rivet.

Check connections: Check connections for firmness and tightness. After the riveting is completed, the rivet should be gently pulled by hand to check whether it is firm. If necessary, a closed rivet sealant can be used to ensure the tightness of the joint.

Test the connection: After installation is complete, the connection is tested to ensure that it can withstand the required stress and vibration. Tests can include tensile tests, shear tests and vibration tests

How to calculate the size of the closed end rivet?

Calculating the size of a closed pop rivets requires consideration of several factors:

- the diameter and length of the rivet. The diameter and length can be determined by measuring the diameter and thickness of the hole of the part.

- the maximum tensile and shear forces of the rivet should be calculated based on the material and stress to ensure that it can withstand the required stress.

What are the advantages and disadvantages of closed pop rivets?

Advantages:

- high strength

- good air tightness

- corrosion resistance

Disadvantages

- high price

- difficulty of installation

In what fields are closed end rivets used?

- automobile manufacturing

- electronic equipment manufacturing

- machinery manufacturing

- construction

- aerospace manufacturing

In automotive manufacturing, closed end rivets can be used to connect various parts and components such as body, engine and chassis, while in electronic device manufacturing, they can be used to connect circuit boards and other components. In construction, closed pop rivets can be used to connect roofs and walls, while in mechanical manufacturing, they can be used to connect parts and components of various machines and equipment.

Frequently Asked Questions

Q: How to choose a suitable closed rivet?

A: Selecting the right closed end rivet needs to consider a number of factors, such as application field, material and stress. Our engineering team can help you select the most suitable closed end rivets.

Q: What are the installation steps of the closed end rivet?

A: Installing closed end rivets requires the use of a rivet gun or other tool. When installing, care should be taken to use the correct rivet gun and the appropriate rivet head. Before installation, the size and material of the parts and rivets should be carefully checked to ensure that they match. The end of the rivet should be properly placed in the part. After riveting, check whether the connection is firm and sealed.

Q: What is the tensile strength of the closed end rivet?

A: The tensile strength of the closed end rivet refers to the maximum tensile force that the rivet can withstand. Tensile strength is usually related to the diameter and material of the rivet. Our closed end rivet products undergo rigorous testing and quality control to ensure they have good tensile strength.

Q: Are closed end rivets suitable for high temperature environments?

A: The material and design of the closed end rivets make them have good resistance to high temperature. However, when using closed end rivets, attention should be paid to the selection of materials and the temperature range of the application environment to ensure that they can work properly.

Q: How does the price of closed end rivets compare to traditional rivets?

A: Due to the higher design and material costs of closed end rivets, they are usually slightly more expensive than traditional rivets. However, considering their advantages and necessity in some application areas, choosing closed end rivets may be a wise choice.

Closed pop rivets, including closed end pull rivets and closed end blind rivets, are important types of fasteners in several industries. Choosing the right closed end rivet for your project requires consideration of several factors, such as application field, material, and stress. Our engineering team can help you select the most suitable closed end rivets. As one of the leading manufacturers of blind rivets, we offer various types of closed rivets to meet the needs of different customers. If you need a closed end rivet solution, please contact our customer service team for more information.