Table of Contents

During industrial production, engineers in various industries use a number of unique fasteners to connect multiple sheet metals and components. What are the best rivets for sheet metal? Do you know the types of rivets used for sheet metal?

Different types of rivets usually have different designs, materials and properties. This article is a comprehensive guide to sheet metal rivets. By reading this article, you will learn about the seven most common types of rivets used for sheet metal assembly, as well as the best rivets for sheet metal.So, when you are choosing new rivets for your business, read this guide carefully.

Table of Contents

The Importance of Sheet Metal Connections

In construction, automotive, aerospace and manufacturing, sheet metal is an essential part of the product components – it’s fair to say that the product couldn’t exist without it, so the connections between them are very important.

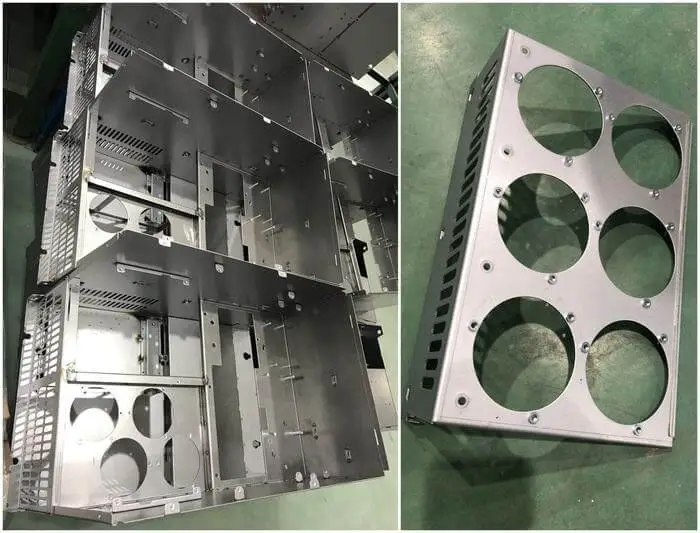

Sheet metal working is a widely used technology in manufacturing and can be used to make a variety of products. This includes automotive parts, electronic equipment housings, appliances, building components, and more. In industry, it is used to meet the specific design requirements of individual products through machining and forming.

Sheet metal is highly flexible and precise, allowing for complex shapes and structures. It provides high strength, light weight, durable and aesthetically pleasing finished products in addition to meeting various product design requirements.

Fasteners, welding, adhesives, folding and bending are generally used to achieve sheet metal connections. This paper focuses on rivets in fasteners.

7 Types Rivets for Sheet Metal

这是测试文本,单击 “编辑” 按钮更改此文本。

1.Solid Rivets

A solid rivet is a mechanical fastener that joins two or more materials. They consist of a cylindrical shaft with a head and a tail at the other end. Solid rivets are usually made of metals such as steel, aluminium or copper.

Solid rivets have the advantage of high strength and resistance to heat and corrosion. However, they are complicated to install and are not removable, which can create new challenges in routine maintenance.

The application scenarios of solid rivets are very wide. These include aerospace, automotive, construction, shipbuilding, electrical and electronic equipment.

2.Tubular Rivets

Tubular Rivets are made up of a hollow cylindrical rivet and a rivet cap. It works by expanding the rivet cap on the other side by hammering or mechanical pressure to form a tight connection.

Tubular Rivets are very simple and economical, making them suitable for high volume production and projects with limited financial budgets.

Tubular Rivets have a low strength, so will be more suitable for leather goods, textiles and other applications that require very little strength.

3.Blind Rivets

Blind rivet, also known as pop rivet, pull rivet. is a fastener that enables quick material connections. Its most important feature is that it can be installed on one side, making it ideal for use in limited spaces where access to the back of the material is not possible.

If you have a specialised rivet tool, you can appreciate how quickly a blind rivet can be installed. Using a blind rivet saves man hours and labour costs and is ideal for mass production and quick installations. But blind rivet is not perfect, it has its drawbacks. The strength of a standard blind rivet may not be up to the task for a high strength application, and this is when you want to opt for a structural blind rivet for the project.

Blind rivet has a very wide range of applications in automotive manufacturing, aerospace, furniture manufacturing, and metalwork. These include, but are not limited to, the joining of body structures, the joining of furniture components, and the assembly and fabrication of metal products.

4.Self Piercing Rivets (SPR Rivet)

Self piercing rivet (SPR Rviet) is a type of rivet that does not require pre-drilling and is particularly suitable for non-penetrating materials.SPR Rivet consists of two parts: the rivet and the rivet sleeve. During installation, the rivet passes through the upper layer of the material and then the rivet sleeve is formed to achieve a stable connection.

The SPR Rivet is a type of rivet, but it does not require pre-drilling. Aluminium alloys, high-strength steels and composite materials are ideal for use with SPR Rivets. SPR Rivet does not require melting or heating and has a very low thermal impact on the material, preserving the properties and structural integrity of the material.

However, SPR Rivet requires specialised equipment and tools for its installation.

SPR Rivet is used extensively in the joining of metal components, including car doors, bonnets and chassis, as well as in the assembly of mobile phone and computer housings.

5.High Strength Structural Rivets

High strength rivets is a category in blind rivet. The traditional Blind rivet has no way to withstand ultra-high strength applications, so structural rivets were invented. A high strength structural rivet is a rivet specifically designed to withstand high strength loads and provide a reliable connection. It generally has special construction and materials to meet the requirements for strength, durability and fatigue resistance.

High strength structural rivets have good fatigue resistance in addition to providing a high strength connection. Compared to traditional bolting and welding, structural rivets allow for a lighter weight design, reducing overall weight without reducing the strength of the connection.

However, structural rivets must be installed using specialised equipment, although they are still very quick to install. Certain non-metallic materials cannot be used with structural rivets.

Structural rivets are often found in industrial applications where strength is required. These include automotive manufacturing, railway and transport engineering, solar energy projects, and more.

6.Lockbolt Rivets

The lockbolt rivet consists of a rivet and a collar. During installation, the rivet needs to pass through the material and then the collar locks the rivet to form a stable connection.

The lockbolt rivet provides an ultra-high strength joint that can withstand extremely high shear and tensile forces. lockbolt rivet has excellent resistance to vibration and loosening, making it ideal for joining in vibrating environments, which is why railways use a lot of lockbolt rivets for their connections. it can also be used to join a wide range of materials, including metals, plastics, and composites, etc.

7.Speed Rivets

Speed rivet is a rivet that can be fully mechanically and automatically installed. It is a non-structural fastener that often joins sheet metal materials.

Speed rivets are often made from lightweight materials such as aluminium alloys to reduce overall weight. And it’s low cost makes it ideal for high volume use.

However, Speed rivet is not as strong and is suitable for applications where strength is not required. It is also not removable. If the connection needs to be addressed. Then the rivet itself usually needs to be destroyed.

Can You Use Aluminum Rivets on Sheet Metal?

Yes, aluminium rivets can be used in sheet metal. Aluminium rivets are commonly used to join sheet metal components and are particularly suitable for sheet metal made of aluminium or other soft materials.

Aluminium rivets offer several advantages in sheet metal applications:

- Lightweight: Aluminium rivets are lightweight and suitable for applications where weight reduction is required, such as automotive or aerospace applications.

- Corrosion resistance: Aluminium naturally forms a protective oxide layer that helps resist corrosion. This makes aluminium rivets suitable for outdoor or corrosive environments.

- Compatibility: Aluminium rivets are compatible with aluminium sheet metal and other soft materials, providing a secure and reliable connection.

- Ease of Installation: Aluminium rivets are relatively easy to install using standard rivet guns or hand tools. The installation process is similar to other solid rivets.

How long Should A Rivet be for Sheet Metal?

For sheet metal, determining the length of rivets requires consideration of several factors, including the thickness of the sheet metal and the requirements of the specific application. In general use cases, rivets should be of a length that allows for full insertion and a secure connection.

So how should we choose the correct rivet length? It can be considered based on the following aspects:

Clamping Range

Clamping range is the total thickness of the material being riveted together. A proper rivet length should be greater than the total thickness of the material. The rivet should be long enough to pass through all sheet metal layer thicknesses and allow sufficient length to form a proper rivet head.

Minimum Protrusion

The rivet should have sufficient projection on the other side of the sheet metal to ensure a strong and secure connection. It is generally recommended that the projection be at least 1.5 times the diameter of the rivet.

Consider Expansion Allowance

If the sheet metal may expand or contract due to temperature changes, the rivet length should be selected with the potential movement in mind. Sufficient clearance should be provided to accommodate any thermal expansion without creating stress or distortion in the joint.

What is the Riveting Process in Sheet Metal?

Conclusion

Rivets are a simple and safe solution for sheet metal joining. Not only does it provide the required joint strength, it also enhances the aesthetics of the sheet metal. The choice of rivet is based on the material, thickness and strength requirements of the sheet metal.

Rivets are perfect for most of the requirements of sheet metal and are not only quick and easy to use, but also economical.

We just need to use the right tools when installing these rivets, taking care of galvanic corrosion between different metals.

Rivmate Riveting Solutions Help You Complete Your Business

After understanding so considerations that we have mentioned in this blog, we hope that you have got a clear idea about sheet metal rivets. Just follow the guidelines we have mentioned in this article and you will be able to choose and buy the best rivets for your business.

We at Rivmate Rivet offer a full range of rivets. Visit our website or contact us today to start providing secure connections for your business or project!