Table of Contents

When it comes to sheetrock connections, there are many options. One of the most popular is the blind rivet. blind rivets have many advantages over other types of connecting fasteners. Let’s take a look at the advantages and disadvantages of pop rivets.

Table of Contents

What is A Pop Rivet?

Pop rivet is a connecting fastener that can be installed on one side. It is often used in situations where the backside of the connected component cannot be accessed.

It is a very practical fastener. Efficient installation, a wide range of material options and good connection performance make it an important connection in aerospace, automotive, construction, home appliances and electronics.

The origins of Pop Rivet: Although pop rivet is now the number one choice for thin sheet connections, the technology was originally developed at the beginning of the 20th century.

Blind rivet joining solutions have proven to be far superior to other fastening products in all aspects of thin sheet joining, which is why pop rivets have become the number one choice for thin sheet joining in just over 100 years.

How Do Pop Rivets Work?

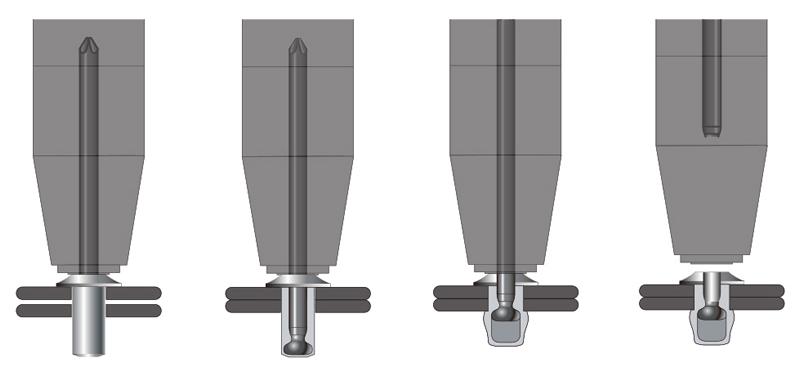

Pop rivet works simply. It creates a stable connection by squeezing the rivet body and causing it to expand. I will briefly describe how it works below:

The Pop rivet consists of two parts, the rivet body and the mandrel. They can be made of the same material or different types of materials. It depends on your requirement. All you need to do is to use a special rivet installation tool and then pull the mandrel to apply pressure. This causes the rivet body to expand and fill the hole. Then you can form a stable connection!

Advantages of Pop Rivets

Blind rivet has a number of advantages over other thin plate connection methods. Therefore, the traditional thin plate connection is being replaced by pop rivets. We have mentioned some of the advantages of pop rivets as follows:

Unilateral Mounting

One-Sided Installation is a significant advantage of blind rivets. It allows the rivet to be installed and fixed from only one side. This feature makes blind rivets very useful in many applications, especially in the following situations:

- Aerospace: the joining of aircraft fuselages and internal structures, where many parts can only be operated from one side, either externally or internally.

- Automotive manufacturing: the connection of bodies and chassis, especially in areas that are difficult to access during assembly.

- Building construction: connection of metal frames, supports and other structural elements, especially when working at height or in confined spaces.

- Household appliances: fixing of appliance housings and internal components to ensure aesthetics and stability.

- Electronic equipment: assembly of internal components of electronic equipment to achieve firm connections in confined spaces.

Procedure for Single Side Mounting

Mounting steps:

- Drill holes: first, drill an appropriately sized hole in the two or more workpieces to be joined.

- Insert the Rivet: Insert the core-pulling rivet into the drilled hole, making sure that the cap (head) of the rivet is close to the surface of the workpiece.

- Pull Rivet Core: Using a specialized pulling or rivet gun, pull the core from the exposed end of the rivet. The pulling gun will pull on the core bar inside the rivet, causing it to expand and fill the hole while clamping the workpiece securely together.

- Break Rivet Core: After the core bar of the rivet has been pulled to a certain point, it will break at its intended breaking point, securing the rivet in the hole. The broken mandrel usually remains inside the rivet, adding to its structural strength.

Tools for Use

Manual rivet gun: suitable for small quantities and need to be flexible occasions, lightweight and easy to operate.

Pneumatic riveting gun: using compressed air to provide power, suitable for high-volume production lines, fast and labor-saving.

Electric Rivet Gun: driven by electricity, simple operation, suitable for different scale of production needs.

Wide Application

Material Diversity

Blind Rivets can be used to join many different materials, here are a few common materials and their characteristics:

Metal:

Steel: provides high strength and is used in applications that require strong fastening, such as construction and heavy equipment.

Aluminum: Lightweight and corrosion resistant, widely used in aerospace and automotive manufacturing.

Stainless steel: good corrosion resistance, suitable for wet or corrosive environments such as marine engineering and chemical equipment.

Copper: Good conductivity for electrical and electronic applications.

Plastics:

Engineering plastics: e.g. nylon, ABS, etc., suitable for lightweight and corrosion-resistant required applications, such as electronic equipment and household appliances.

Composites:

Glass Fiber Reinforced Plastics (GFRP): lightweight and strong, commonly used in marine and automotive parts.

Carbon Fiber Reinforced Plastics (CFRP): stronger and lighter, widely used in high performance applications such as aerospace and racing.

Multiple Application Scenarios

Aerospace: Aircraft manufacturers such as Boeing and Airbus make extensive use of aluminum blind rivets to join fuselage panels and internal structures, ensuring lightweight and high strength aircraft.

Automotive: Automakers such as Tesla and Ford make extensive use of self-pierce rivets and blind rivets in the joining of their aluminum bodies to improve productivity and body rigidity.

Construction: In high-rise buildings and bridge construction, stainless steel blind rivets are used to connect steel beams and columns to ensure the stability and durability of the structure.

Household appliances: Samsung and LG and other home appliance manufacturers widely use pultruded rivets in the connection of the shell and internal components of washing machines, refrigerators and other products to improve product reliability and aesthetics.

High Strength Connections

Through proper selection of rivet material and size, blind rivets provide strong clamping force and long-lasting durability in a wide range of high-stress and high-vibration applications.

There are many raw materials to make blind rivets, when your project has certain requirements for strength, you can choose high strength steel, stainless steel, aluminum alloy and other metal materials.

Blind rivets can provide strong clamping force. The force of a blind rivet is evenly distributed around the rivet, which reduces stress concentrations and increases the overall strength of the connection.

Blind Rivets can also provide long lasting durability and good resistance to vibration. The rivet body and rivet mandrel work together to prevent loosening and falling off.

Clean Appearance

Blind Rivet leaves a smooth, uncluttered appearance after installation, which makes it very popular in many applications where an attractive and clean look is desired.

Blind Rivets leave a flat surface with no protrusions after installation. And the rivets are installed consistently, creating a uniform visual effect.

The mandrel of the Blind Rivet usually breaks off and becomes embedded within the rivet after installation, with no excess protrusion.

Because of this feature, Blind Rivets are suitable for use on the aluminum case of the Mackbook to ensure that the connection area is flat and smooth. Tesla’s model S also uses blind rivets for its body panels and interior components, enhancing the quality and aesthetics of the body’s appearance. Blind rivets are very much in line with the design requirements of luxury automobiles.

Disadvantages of Pop Rivets

Blind rivet has so many advantages, and of course, people will want to know what are the disadvantages of blind rivet.

All things in the world possess disadvantages and advantages. There is no such thing that has only advantages.Blind rivet also has some disadvantages. Some of the disadvantages are mentioned below:

Limited Strength for Some Applications

Compared to solid rivets and bolts. Blind rivets are generally not as strong as they are. If the blind rivets want to realize the ultra-high strength of the connection, the choice of material of the core bar is very important.

This is because the design of a blind rivet is such that its internal parts are hollow, which reduces the strength of the blind rivet to a certain extent.

For example, in applications such as buildings and bridges, heavy machinery and other highly stressed structures, blind rivets may not be able to provide sufficient strength. Also in applications that require frequent maintenance and disassembly, blind rivets may not provide a good solution. This is because blind rivets are not removable.

Hole Size Requirements

Hole diameter is a very important factor in the strength of a blind rivet. The size and accuracy of the hole directly affects the installation quality of the rivet and the strength of the connection.

A proper hole diameter ensures that the rivet can be inserted smoothly and expansion can occur. Too large a hole may cause the rivet to loosen in the hole, resulting in a weak connection; too small a hole will make the rivet has no way to insert or deformation during installation.

An improperly sized hole may also lead to stress concentrations, increasing the risk of rivet breakage.

Conclusion Remarks

The variety of Blind Rivet is constantly evolving. From the invention of the blind rivet to the present day, a considerable variety has emerged to meet industrial production. In practical applications, we can fully utilize their advantages and fully offset their disadvantages. In spite of its drawbacks, the blind rivet is currently the first choice for thin sheet connections due to its advantages (especially quick installation and consistency).

The advantages and disadvantages of the blind rivet have been presented in detail above. Hopefully, this will help you with your projects and business.

| Advantages | Disadvantages |

|---|---|

| Easy one-sided installation | Limited strength |

| Wide range of applications | Requires special installation tools |

| High-strength connection | Strict hole diameter requirements |

| Clean and tidy appearance | Non-removable |

| High installation efficiency | Limited in high-stress applications |

| Variety of material choices | Affected by hole quality |

| Good vibration resistance | Performance affected by oversized or undersized holes |

| Strong corrosion resistance (depending on material) | Limited for specific applications |

Why Buy Pop Rivets from Rivmate Rivet?

Blind rivet relates to the safety of various programs. So Blind rivet must be purchased from reliable blind rivet manufacturers and suppliers. As the quality of Blind rivet made by different manufacturers varies, you can easily fall prey to low quality Blind rivets suppliers.Rivmate Rivet is a quality supplier offering a full range of Blind rivet solutions.Rivmate is one of the top 3 Blind rivet suppliers in China! Rivmate is one of the top three blind rivet suppliers in China.

Rivmate provides high quality blind rivet solutions at the most cost effective price. Moreover, the company has more than a decade of experience in providing high quality blind rivet solutions.

Rivmate rivet is also a rivet solution provider that can provide customized rivet solutions, which can be customized according to the customer’s requirements relative to the rivet connection solution.

Most trustworthy of all, Rivmate rivets are available with 3 years quality after sales. That is to say, if there is any problem with the rivet within three years, a full refund will be given! This makes the company a highly reliable source of Blind rivet supply for rivet distributors worldwide.

Ready to buy blind rivet from Rivmate? Contact us today!