Sheet Metal Blind Fasteners : A Complete Buying Guide

Table of Contents

Do you know which sheet metal blind fasteners you should use for your sheet metal business? Do you know how you should buy sheet metal blind fasteners that are high quality and affordable? Through this article, you will learn the difference between different blind fasteners and how to choose them!

What Are Sheet Metal Blind Fasteners?

Sheet metal blind fasteners refer to single-sided installation fasteners specifically designed for thin plate structures. This type of fastening method does not require contact with the backside and is suitable for structures with limited space, thin plates, and a closed backside. They form a stable connection between thin plates through structural deformation, tensioning, or locking mechanisms.

In engineering practice, the core meaning of “blind” is that installers can complete the fastening by only accessing one side of the workpiece. Such fasteners are typically used for 0.3–3.0 mm metal sheets, such as steel plates, aluminum plates, and stainless steel plates, and are the most commonly used connection method in the sheet metal industry.

Why Use Blind Hole Fasteners for Sheet Metal?

Blind hole fasteners are the most commonly used fasteners in sheet metal applications. Blind Hole Fasteners have many unique advantages over other fasteners.

- Sheet metal is usually only accessible from one side, and there is no way to solve this problem with traditional joining methods. Blind hole fasteners offer a great solution. It does not require backside access.

- The installation process for blind hole fasteners is very quick. Compared to the installation of other fasteners, blind hole fasteners reduce assembly time and labour costs.

- Blind-hole fasteners create a strong, tight connection that provides excellent vibration resistance.

- Blind hole fasteners can be used with a variety of sheet metal materials including aluminium, steel and conforming materials.

- Conventional fastening methods (e.g. welding or bolting) may cause damage to sheet metal surfaces, including thermal deformation, surface scratches and distortion. Blind hole fasteners do not damage the surface of sheet metal.

Blind hole fasteners provide a practical and efficient solution for joining sheet metal components, minimising the risk of potential workpiece damage.

Common Types of Fastener Used to Join Sheet Metal

Depending on the requirements of your project or business, choices can be made based on factors such as the specific application, required strength, accessibility and aesthetics. Each method has its own installation, cost and overall performance considerations.

There are three common types of blind hole fasteners:

- Blind Rivet

- Rivet Nut

- Self Clinching Nut

a. Blind Rivet

Blind Rivet, as one of the most commonly used assembly fasteners in sheet metal. It is a fast and easy way to connect two or more sheet metal pieces.

Because of its unique characteristics, Blind Rivet is widely used in sheet metal assembly and connection in electronic, electrical, telecommunication, mechanical and other industrial fields for various sheet metal materials and thicknesses.

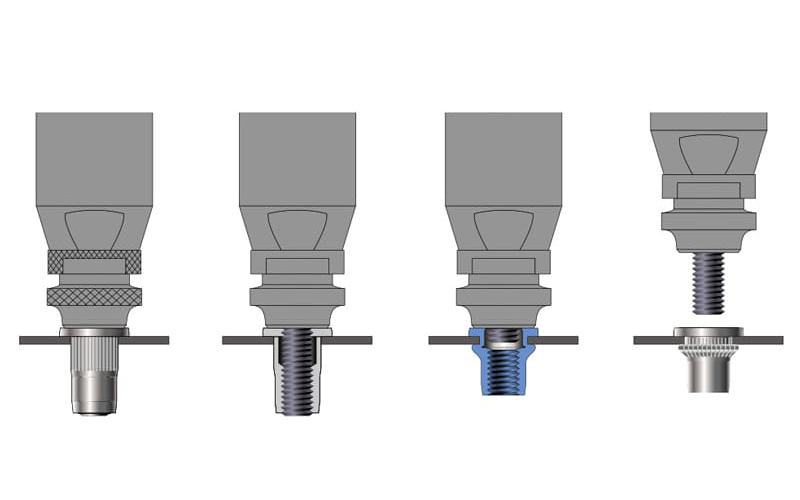

b. Rivet Nut

The Rivet Nut creates an internally threaded connection on sheet metal that can be threaded to provide a connection point for other parts.

Rivet nut is also used in a very wide range of applications on sheet metal. In cases where sheet metal structures need to be strengthened and reinforced, the Rivet Nut can be used to mount reinforcements or add accessories.

The Rivet nut is a simple, cost-effective fastener solution for providing a secure attachment point. It is also suitable for a wide range of sheet metal materials and thicknesses.

c. Clinch Nuts / Clinch Studs

Blind fasteners that provide a stable connection point in sheet metal are not only available as rivet nuts, but also as self clinching fasteners. self clinching fasteners provide a strong connection without the use of additional nuts, bolts or screws.

Self clinching fasteners are ideally suited for thin sheet metal and limited mounting controls that can be installed into the sheet metal by mechanical pressure or pressure equipment.Self clinching fasteners are used in sheet metal assemblies in the automotive, electronics, aerospace, electrical equipment and other industries.

How Do Blind Fasteners Work?

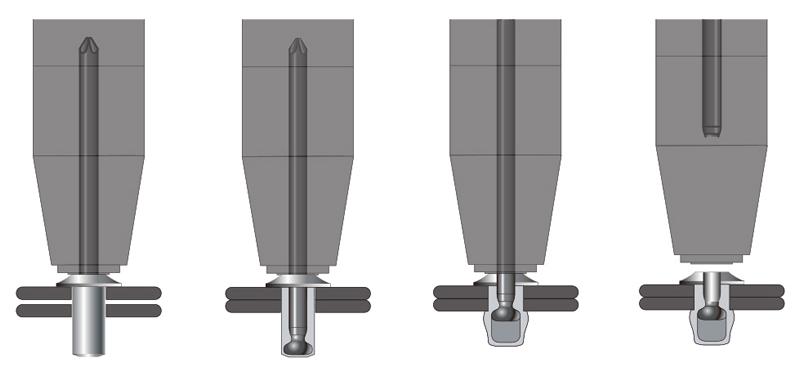

Different types of blind fasteners work differently. Blind rivets and rivet nuts work in a very similar way, by using a tool to deform and expand the end of the fastener to tighten the connection.

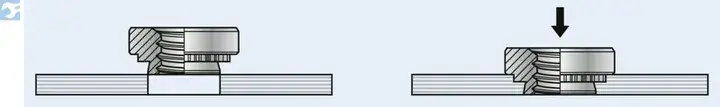

Self-clinching nuts are made by pre-punching holes in thin plates and then pressing the nuts into the holes with a press. The annular knurl and undercut on the outer ring of the nut will be embedded into the metal sheet. During the riveting process, the sheet undergoes a slight plastic flow, filling the toothed grooves of the nut, thereby forming a permanent lock.

Performance Comparison of Sheet Metal Blind Fasteners

When choosing the appropriate blind fasteners, a systematic assessment must be made from the performance dimension. Different types of fasteners have obvious differences in structural strength, waterproofing ability, installation methods and costs.

Sheet Metal Blind Fasteners:Performance Comparison Table

| Performance Aspect | Blind Rivet | Rivet Nut | Clinch Nut / Clinch Stud |

|---|---|---|---|

| Tensile / Shear Strength | Medium to high; stable structure | Depends on sheet thickness; moderate shear strength | High; excellent tensile and torque resistance |

| Vibration Resistance | High; connection does not loosen | Good, but long-term vibration may affect threads | High; ideal for equipment structural parts |

| Waterproof Performance | Closed-end type can be fully sealed | Average; requires O-ring | Average; not a sealing structure |

| Removability | Non-removable | Removable; suitable for maintenance | Removable and structurally stable |

| Material Thickness Compatibility | 0.3–3.0 mm | 0.5–6.0 mm | 0.8–3.0 mm |

| Installation Speed | Fast | Medium (requires rivet nut tool) | Medium (requires press machine) |

| Cost | Low | Medium to high | Medium |

1. Tensile / Shear Strength

The overall strength of blind rivets is higher than that of Rivet Nut, especially for structural blind rivets, which are suitable for dynamic loads and vibration environments.

The tensile strength of the self clinch nuts and studs is the best, as they rely on the “embedding + interlocking” of the material.

2. Anti-vibration Stability

Blind rivets perform best in a vibrating environment due to their mechanical locking structure. The threaded part of the Rivet Nut may loosen due to vibration, and anti-loosening measures are required.

3. Waterproofing Capacity

If used for roofing, outdoor applications or HVAC enclosures, the closed-end type of blind rivets is the best choice. For other types, additional sealing measures are required.

4. Disassembly Capability

Rivet Nut and self-clinching parts provide threads and can be easily disassembled, which is something that blind rivets cannot achieve. They are suitable for equipment that requires maintenance or for electronic enclosures.

5. Compatibility of Material Thickness

- Blind rivets are most suitable for thin plates (0.3 – 3 mm).

- Rivet Nut offers a wider range of thickness requirements and is the best solution for providing threads on thin plates.

- Self-clinching nuts/screws are suitable for steel plates ranging from 0.8 to 3 mm.

6. Installation Speed

Blind rivets are the fastest and they are suitable for large-scale and rapid manufacturing.

7. Cost Analysis

Blind rivets are the most cost-effective solution and are suitable for a large number of sheet metal parts. Although Rivet Nut and self clinch fasteners have higher unit prices, they meet maintenance requirements and have a lower life cycle cost.

How to Choose the Right Blind Fastener for Sheet Metal

When choosing suitable blind fasteners for thin plates, it is necessary to follow engineering logic rather than relying solely on empirical judgment. Different fasteners vary significantly in terms of force application, material compatibility, sealing ability and maintenance methods.

a. Material Thickness Compatibility

The thickness of the sheet material is the primary key factor in selection. Because the strength of the thin sheet is limited, the thinner the sheet, the less suitable it is for tapping or traditional screws, and the higher the failure probability.

- 0.3–1.0 mm → Preferably use Blind Rivet or self-drilling blind fasteners

- 0.8–3.0 mm → Use Blind Rivet / Clinch Nut / Clinch Stud

- 1.0–6.0 mm → Use Rivet Nut (providing threaded capability)

b. Selection based on materials

The matching principles for different materials are different:

Steel plate→ All types of blind fasteners are applicable

Aluminum plate → Recommended aluminum rivets, light-load Rivet Nut

Stainless steel plate (SS) → Recommended stainless steel Rivet Nut / Clinch Nut (to avoid electrochemical corrosion)

Avoid the combination of “aluminum rivets + stainless steel plates” as it can cause electrochemical corrosion.

c. Need Threaded Connection

Need to be detachable/maintainable → Rivet Nut or Clinch Nut

No need for threads, for permanent connection → Blind Rivet is the best choice

Rivet Nut is usually the preferred choice for chassis enclosures and electrical control boxes.

Outdoors, roof, curtain wall → Closed-End Blind Rivet

General indoor use → Either Blind Rivet or Rivet Nut can be used

According to the salt fog test data from Rivmate: The closed-end rivets remained free of rust after 1000 hours of testing.

e. Vibration & Dynamic Load

High-vibration structures (such as equipment casings, mechanical devices) → Blind Rivet / Structural Blind Rivet / Clinch Nut

Low vibration → Rivet Nut is sufficient

Reason: The threads are more likely to loosen under long-term vibration.

Best Blind Fasteners for Different Sheet Metal Applications

In real engineering and mass production, the selection of Blind Fasteners must be based on the specific application scenarios rather than solely considering the structural appearance or cost. Different scenarios have different load patterns, maintenance requirements, environmental conditions and production schedules.

Home Appliances Industry

Recommendation: Blind Rivets + Rivet Nuts The exteriors of household appliances are usually made of thin plates ranging from 0.4 to 0.8 mm in thickness, and the materials are mostly galvanized steel plates or aluminum plates. The thin plates have low strength and screws are prone to come loose, therefore:

Blind Rivet → A component used for permanent and maintenance-free assembly points

Rivet Nut → Used for structures that require later disassembly and assembly, such as motors, control boards, and filters.

This combination has become the industry standard in the fields of refrigerators, washing machines and air conditioners.

Sheet Metal Enclosures & Cabinets

Recommendation: Rivet Nuts + Clinch Nuts

The cabinet structure requires a large number of detachable threaded points, and the thickness of the boards is mostly between 0.8 – 2.0 mm. Therefore, the most suitable configuration is:

Rivet Nut → Suitable for thin plates and locations where the riveting process cannot be used.

Clinch Nut / Clinch Stud → High-strength, anti-twisting, long thread lifespan

For example, server enclosures, electrical cabinets, and communication equipment boxes all use this combination.

Outdoor Cladding and Building Exterior Finishing

Recommendation: Closed-End Blind Rivets

The curtain wall system has extremely high requirements for waterproofing and corrosion resistance. The advantage of the closed-type Blind Rivet lies in:

- 100% sealed

- The core shaft is locked and has excellent vibration prevention effect

- Optional stainless steel material, resistant to salt spray for over 1000 hours

- Stable installation, suitable for high-altitude construction

Therefore, it is widely used in aluminum panels, metal roofing, and structural facades.

Automotive Manufacturing

Recommendation: SPR (Self-Piercing Rivets) + Structural Blind Rivets

The automotive body structure is subjected to multi-directional loads and complex working conditions, and requires high-strength connections:

SPR Self-Drilling Rivet (for lightweight aluminum sheets in vehicle body): No need for pre-drilling, one-sided installation, high strength.

Structural Blind Rivet (Suitable for Steel Plates and Composite Materials): Equipped with a mechanical locking core, it does not loosen and has excellent fatigue resistance.

HVAC & Ventilation Units

Recommendation: Sealed / Waterproof Blind Rivets

HVAC equipment involves condensate water, pressure fluctuations, and temperature cycling. The closed-end rivets or waterproof Blind Rivets with sealing gaskets are the most stable options.

Get Expert Guidance for Your Sheet Metal Fastening Needs

In thin plate structures, blind fasteners are almost an indispensable solution. They support one-sided installation, are compatible with thin materials, can achieve high-strength connections, and perform stably and reliably in terms of waterproofing, vibration resistance, and corrosion prevention. Whether you use blind rivets, rivet nuts, press rivets, or self-drilling blind fasteners, correct selection will significantly enhance product lifespan and assembly efficiency.

If you are looking to select the best Blind Fastener for your project, please feel free to contact the Rivmate Engineering Team. We can offer you the following: Free sample delivery (for mass production verification); recommendations on plate thickness and load selection.

📧 Product Inquiry: manufacture@world-rivet.com

🌐 Official Website: https://worldrivet.com/

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met