What is a Lockbolt Rivet?

Table of Contents

In modern manufacturing and structural engineering, Lockbolt Rivet is gradually becoming a high-strength fastening solution to replace traditional bolts and rivets. This article will comprehensively analyze the definition, structural principle, installation method, performance advantages and typical applications of Lockbolt Rivet from a professional perspective. At the same time, we will also conduct an in-depth comparison of the differences between Lockbolt and Rivet to help you select the appropriate fastening solution for a specific engineering project.

Definition and Structure of a Lockbolt Rivet

Lockbolt Rivet consists of two main parts: Pin and Collar. Unlike traditional rivets, Lockbolt does not rely on the breaking of the mandrel or welding to form a fixed structure. Instead, it achieves stable and long-lasting structural locking through the mechanical interlocking of the lock ring and the stud. This design ensures that the connection points can remain reliable even under high vibration, high load or harsh environments.

Structurally speaking, the Lockbolt rivet structure mainly consists of the following parts:

- Pin : The main body is usually made of high-strength steel or stainless steel, featuring a smooth rod body and a tail with multiple grooves.

- Collar: A ring-shaped metal kit that is pressed into the nail bar slot by hydraulic or pneumatic tools during installation and achieves a 360° mechanical locking through plastic deformation.

- Installation Tool : A dedicated hydraulic or pneumatic fixture used to control the press-in force and stretching stroke to ensure consistent locking.

According to international industrial standards, the manufacturing and testing of Lockbolt Rivet usually follow the following specifications:

- ISO 16120: Standard for mechanical properties of metal fasteners

- NAS1919 : Specification for Riveting Lock Bolts for Aviation Use

- ASTM F2281 : Technical Standard for Structural Lock Bolt Fasteners

In terms of the fastening principle, Lockbolt Rivet is a pure mechanical locking structure, with no risk of thread loosening and no heat-affected zone of welding. This design makes it the preferred choice for industrial connections with extremely high requirements for safety and durability.

How Does a Lockbolt Rivet Work?

To understand the source of the strength of Lockbolt Rivet, it is necessary to first understand its installation and locking principles. Unlike ordinary rivets that break through a mandrel, Lockbolt achieves permanent connection through the mechanical interlocking of the stud and the lock ring. This structure ensures uniform force distribution, strong vibration resistance, and stability under extreme working conditions.

- During the pressing process, the lock ring will undergo plastic flow, achieving a high contact area locking.

- Measured data shows that the shear strength of Lockbolt is usually 30% to 50% higher than that of structural blind rivets.

- Due to the absence of thread loosening risk, its vibration resistance and fatigue life are significantly better than those of bolt connections.

The following are the standard installation steps:

Step1: Insert the Pin

Insert the Lockbolt Pin into the pre-drilled hole, ensuring that the hole diameter matches the pin and the gap does not exceed 0.2mm. Nail rods are usually made of high-strength alloy steel or stainless steel and can withstand considerable tensile and shear forces.

Step2: Fit the Collar

Insert the Collar into the groove area at the tail of the nail bar. The inner diameter of the lock ring is slightly smaller than that of the nail bar slot, providing plastic deformation space for subsequent press-in. This step determines the tightness of the lock. It is essential to ensure alignment and no skew.

Step3: Pull and Swage the Collar

Use a dedicated Lockbolt installation tool (hydraulic or pneumatic type) to hold the tail of the nail bar and stretch it backward, while pressing the lock ring into the slot under high pressure. This process will cause plastic deformation of the lock ring material, forming a 360° circular lock, thereby achieving a firm mechanical fit.

Step4: Break the Pintail

When the lock ring is fully pressed in and the locking is completed, the tool will automatically disconnect the tail of the pin rod at the preset cutting point. At this point, the connection has been permanently fixed and cannot be loosened, nor does it require later maintenance.

In the field of industrial fastening, both Lockbolt Rivet and Pop Rivet (blind rivets) are widely used permanent fasteners. However, there are essential differences between the two in terms of structural design, installation methods and performance.

| Comparison Criteria | Lockbolt Rivet | Pop Rivet (Blind Rivet) |

|---|---|---|

| Installation Method | Requires access from both sides; collar is swaged onto the pin using a hydraulic or pneumatic tool for mechanical locking | Installed from one side only; mandrel is pulled and snapped to form the joint |

| Strength Level | High-strength structural connection suitable for long-term load-bearing and heavy-duty applications | Medium strength; ideal for thin sheets and light-duty assemblies |

| Vibration Resistance | Excellent — the locking collar design prevents loosening under vibration | Moderate — may experience slight loosening under continuous vibration |

| Removability | Permanently locked and non-reusable | Non-removable but can be drilled out for disassembly |

| Typical Applications | Railway vehicles, bridge structures, wind power equipment, heavy machinery | Automotive panels, household appliances, industrial assembly |

| Cost | Higher initial cost but minimal maintenance over time | Low cost, suitable for large-volume production |

From the perspective of structural safety and service life, Lockbolt Rivet is more suitable for engineering applications that withstand long-term loads and frequent vibrations, especially for the main load-bearing structures of railways, buildings and heavy equipment.

And Pop Rivet is more suitable for medium and light assembly and daily industrial manufacturing due to its characteristics of lightness, low cost and easy installation.

Key Advantages of Lockbolt Rivets

In structural fastening systems, Lockbolt Rivet is renowned for its outstanding mechanical properties and long-term stability. Compared with traditional rivets or bolts, Lockbolt not only offers higher strength but also maintains reliable locking in extreme environments. The following are its core advantages:

Superior Shear and Tensile Strength

The design of Lockbolt can withstand high-load impacts and continuous stress. The mechanical interlocking of its nail rods and lock rings can maintain high-strength stability in structural connections, making it suitable for heavy-duty structures such as Bridges, rail vehicles, and engineering equipment.

Outstanding Vibration Resistance

The lock ring system of Lockbolt achieves 360° circular locking through plastic deformation, effectively preventing connection loosening in high-frequency vibration or shock environments. It is an ideal choice for frequently vibrating equipment such as railway vehicles and wind power towers.

High consistency and Precise Installation

Installation using hydraulic or pneumatic tools can ensure that the clamping force and deformation at each connection point are consistent, avoiding the errors caused by traditional bolt tightening. This is particularly important for large-scale industrial assembly.

Maintenance-Free Design

Once installed, Lockbolt does not require secondary tightening or regular maintenance. Its stable mechanical locking structure ensures almost zero loosening during long-term operation, making it an ideal solution for reducing maintenance costs.

No Threads, No Welding

Lockbolt does not require threaded connections and does not produce a heat-affected zone (HAZ) during welding. This not only avoids metal fatigue but also maintains the strength of the base material unchanged.

Applications of Lockbolt Rivets

Lockbolt Rivet, as a structure-grade high-strength fastener, has been widely applied in multiple key industries due to its outstanding vibration resistance and long-term stability. It can maintain reliable locking under high loads, high-frequency vibrations and extreme environments.

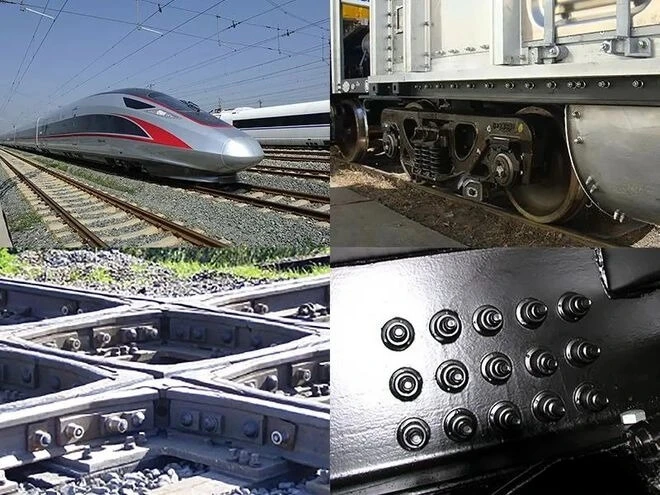

- Railway Rolling Stock

Lockbolt is one of the core fastening solutions in railway vehicle manufacturing. Whether it is the connection of the carriage frame, bogie, or the assembly of the chassis frame, Lockbolt can provide long-lasting connection performance that is resistant to loosening and fatigue. Compared with traditional welding, it avoids thermal deformation problems and ensures the long-term stability of the structure. - Heavy Machinery

In high-vibration equipment such as excavators, cranes and mining machinery, Lockbolt can withstand continuous impact and shear force. Its high-strength locking ring system ensures a zero-loosening state even under heavy-load cycle conditions, significantly enhancing the reliability and service life of the equipment. - Bridge and Steel Structure

For large steel structures such as Bridges and towers, connection strength and durability are of vital importance. The Lockbolt system can maintain structural rigidity under high wind and dynamic loads, and is easy to install, making it suitable for on-site construction and high-altitude assembly. - Wind Power Towers

Wind power equipment is constantly exposed to strong winds, high humidity and heat, and salt spray environments. The corrosion resistance and vibration resistance performance of Lockbolt Rivet make it the first choice for tower assembly and generator base fixation.

Rivmate Expert Recommendations

In different industrial assembly scenarios, the selection of fastening schemes directly affects structural strength, production efficiency and later maintenance costs. Based on long-term industry experience, the Rivmate engineering team has summarized the following three key suggestions to help users make a more precise choice between Lockbolt and Rivet systems.

If lightweight and medium-strength connection are pursued → Choose Structural Blind Rivet

This type of rivet is easy to install and can be operated on one side, making it suitable for medium-strength structures and light equipment. It can reduce weight while maintaining sufficient shear resistance and assembly efficiency, making it highly suitable for automotive, home appliance and general sheet metal assembly.

If high load and seismic stability are required → The Rivmate Lockbolt System is the first choice

Lockbolt features a higher mechanical locking force and fatigue resistance, ensuring zero loosening in environments with strong vibration and heavy loads. The Rivmate Lockbolt system is particularly suitable for projects that require long-term structural stability, such as railway vehicles, bridge structures, and wind power equipment.

For batch production lines → Use the Rivmate hydraulic installation tool series

Hydraulic assembly tools can ensure that the clamping force at each connection point is consistent, reduce human errors and increase the production rhythm. The Rivmate tool system is compatible with a variety of nail diameters and materials, significantly enhancing assembly consistency and production line efficiency.

In the field of industrial fastening, there is no “one-size-fits-all solution”. The selection should be made comprehensively based on the structural strength requirements, assembly methods, usage environment and production scale. Rivmate, through its Lockbolt System, Structural Rivets and dedicated installation equipment, can provide reliable and efficient overall solutions for different working conditions.

FAQ

Lockbolt Rivet is mainly used for structural connections that require high strength, vibration resistance and long-term stability. Typical applications include railway vehicles, bridge structures, wind power towers, heavy machinery and building steel structures. It is a permanent locking fastener, especially suitable for long-term loads and strong vibration environments.

Q2. Is a Lockbolt stronger than a rivet?

Yes. Lockbolt is typically 30% to 50% stronger than structural rivets of the same specification. The mechanical locking structure between its nail bar and lock ring can provide higher shear and tensile performance, and at the same time, it has excellent fatigue life resistance, making it very suitable for heavy-load or high-frequency vibration applications.

Q3. How is a Lockbolt installed?

The installation process is divided into four steps:

① Insert the nail rod into the hole;

② Put on the lock ring;

③ Use hydraulic or pneumatic tools to press the lock ring into the nail bar slot;

④ When the locking is completed, the tail of the nail bar automatically breaks to form a permanent lock.

The entire process is fast, safe and has a high degree of assembly consistency.

Q4. Can Lockbolts replace welding?

In most structural assemblies, Lockbolt can indeed partially replace welding. It does not require high-temperature heating and will not produce a heat-affected zone (HAZ), thus avoiding metal fatigue and deformation. More importantly, it requires no later maintenance and can immediately bear structural stress, thus being widely used in the connection of steel structures and aluminum alloys where welding is inconvenient.

Q5. Are Lockbolts reusable?

No. Lockbolt is a type of permanent fastener. After installation, it forms a fixed structure through the plastic deformation of the lock ring. If disassembly is required, the lock ring must be drilled out or the nail bar cut off. However, this design ensures that it remains in a zero-loosening state throughout its service life, which is a key guarantee for structural safety.

As an important technological innovation in the field of structural fastening, Lockbolt Rivet represents the best balance of high strength, zero loosening and long-term reliability. It achieves permanent fastening through the Mechanical Collar Locking structure and can still maintain a stable connection in environments such as strong vibration, high load, and extreme weather.

Professional advice from Rivmate:

If your project has strict requirements for structural safety, vibration resistance performance or corrosion resistance, Rivmate Lockbolt System is the most reliable solution. Rivmate has many years of industrial application experience. Its products comply with ISO/ASTM international standards and can provide you with all-round technical support from selection, installation to long-term maintenance.

👉 Visit Rivmate Engineering Fastening Center immediately for professional selection guidance and engineering application consultation.

Reference

How to Rivet Metal to Wood?

How to Rivet Metal to Woo

What Is Riveting in Metal Work?

What Is Riveting in Metal

What Metal Are Rivets Made Of

What Metal Are Rivets Mad

How to Rivet Metal to Metal

How to Rivet Metal to Met