SPR Rivet (Self Piercing Rivet)

Rivmate Self Piercing Rivet Supplier – Provide Security For Your Project With High Sterngth SPR Rivet

SPR Rivet for High-Efficiency Industrial Assembly

SPR Rivet (Self Piercing Rivet) is a mechanical fastener that requires no pre-drilling, widely used for efficient assembly of thin sheet metals and dissimilar materials. Unlike traditional blind rivets that necessitate pre-drilling and create through holes, SPR Rivets reduce process steps and cause less damage to coatings and plating. It also delivers superior fatigue resistance and assembly stability when joining multi-layer sheets and dissimilar materials (e.g., aluminum-steel, aluminum-aluminum). Consequently, it has become a critical joining solution in automotive manufacturing, lightweight structures, and high-end industrial assembly.

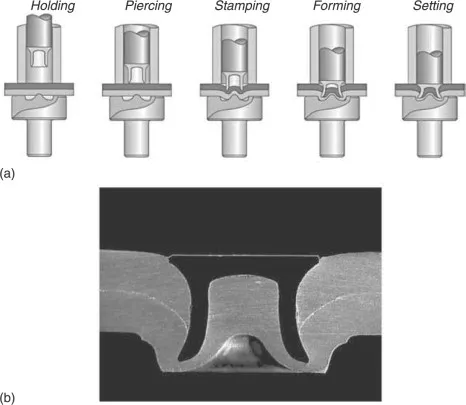

How SPR Rivets Work

The SPR Rivet (Self Piercing Rivet) achieves connection through three consecutive steps: piercing, forming, and locking. Under high pressure and using specialized equipment and dies, the rivet penetrates the upper material while simultaneously inducing controlled plastic flow in the lower material. This process creates a stable mechanical interlocking structure without forming a through-hole. Since the joining process relies on material forming rather than cutting, SPR Rivets eliminate the need for pre-drilling, significantly reducing process steps and enhancing assembly consistency. The fundamental requirements for the base material are sufficient thickness and good ductility to ensure the underlying material can be fully formed and achieve reliable locking.

| Material | Carbon Steel |

| Head Type | CSK |

| Quality Authentication | IATF16949,ISO14001,ISO45001 |

| Surface | Zinc plated/Natural polish |

| Size | 3.3 - 5.3 |

| Own factory? | YES |

| Customized services | YES |

| Standard | ISO,DIN7337,IFI114,HUCK,AVDEL etc |

The Technical Specification of Self Piercing Rivet(SPR RIvet)

| Part Number | Size | D | L | Quantity |

|---|---|---|---|---|

| SSPRA53040 | 5.3×4 | 5.3 | 4 | 5000 Only/dsk |

| SSPRA53050 | 5.3×5 | 5.3 | 5 | |

| SSPRA53055 | 5.3×5.5 | 5.3 | 5.5 | |

| SSPRA53060 | 5.3×6.0 | 5.3 | 6 | |

| SSPRA53065 | 5.3×6.5 | 5.3 | 6.5 | |

| SSPRA53070 | 5.3×7.0 | 5.3 | 7 | |

| SSPRA53075 | 5.3×7.5 | 5.3 | 7.5 | |

| SSPRA53080 | 5.3×8.0 | 5.3 | 8 | |

| SSPRA53090 | 5.3×9.0 | 5.3 | 9 | |

| SSPRA53100 | 5.3×10.0 | 5.3 | 10 | |

| SSPRA53120 | 5.3×12.0 | 5.3 | 12 | 4000 Only/dsk |

| SSPRA33035 | 3.3×3.5 | 3.3 | 3.5 | 10000 Only/dsk |

| SSPRA33040 | 3.3×4.0 | 3.3 | 4 | |

| SSPRA33050 | 3.3×5.0 | 3.3 | 5 | |

| SSPRA33060 | 3.3×6.0 | 3.3 | 6 |

WHY USE IT

Key Advantages of SPR Rivets

No Pre-Drilling Required

SPR Rivets eliminate the need for pre-drilling, reducing machining steps, shortening assembly cycles, and significantly boosting overall production efficiency.

High Joint Consistency

The riveting process is controlled by equipment and dies, ensuring stable forming and high joint consistency. This makes them particularly suitable for automated and mass production lines.

Excellent for Multi-Layer Stacks

Creates reliable interlocking structures within multi-layer panels, preventing interlayer slippage and enhancing overall joint stability.

Ideal for Dissimilar Materials

Suitable for dissimilar material combinations like aluminum-to-steel or aluminum-to-aluminum, avoiding compatibility issues common in welding or bolted connections.

Minimal Damage to Coatings

Does not create through-holes during connection, causing minimal damage to surface coatings and plating to help maintain material corrosion resistance.

Good Fatigue and Vibration Resistance

The mechanical interlocking structure effectively distributes loads, maintaining stable connections under vibration and cyclic loading conditions to enhance long-term reliability.

SPR Rivet vs Other Fastening Methods

SPR Rivet vs Other Fastening Methods for Industrial Assembly

| Comparison Aspect | SPR Rivet (Self Piercing Rivet) | Blind Rivet | Spot Welding | Flow Drill Screw |

|---|---|---|---|---|

| Pre-Drilling Required | No | Yes | No | No |

| Joining Principle | Piercing + forming + mechanical interlock | Pull mandrel riveting | Fusion welding | Thermal drilling + threaded fastening |

| Through-Hole Formation | No | Yes | No | Yes |

| Suitability for Dissimilar Materials | Excellent | Fair | Poor | Fair |

| Automation Compatibility | Very high | Medium | High | Medium |

| Impact on Coatings | Minimal | Moderate | Significant | Moderate |

| Fatigue Resistance | High | Medium | Medium | Medium |

| Rework & Consistency | High consistency, low rework rate | Dependent on hole quality | Dependent on weld quality | Dependent on thread quality and torque |

| Typical Applications | Automotive, lightweight structures | Sheet metal assembly | Body-in-white welding | Thick sheets or local reinforcement |

SPR Rivet vs Blind Rivet

- Pre-drilling Required: SPR Rivets require no pre-drilling, achieving penetration and forming directly during assembly. Blind Rivets necessitate pre-drilling, involving more steps and greater reliance on prior machining processes.

- Hole Positioning & Assembly Consistency: Blind Rivet connection quality heavily depends on hole diameter, positioning, and wall integrity. SPR Rivets do not create through holes; connection consistency is controlled by equipment and tooling, offering higher batch stability.

- Structural Integrity: SPR Rivets do not create through holes, helping preserve the integrity of underlying materials. Blind Rivets form through holes, which may weaken local strength in thin sheets or lightweight structures.

- Production Efficiency: SPR Rivets typically achieve shorter cycle times on automated lines due to reduced drilling and deburring steps, making them suitable for high-volume production.

SPR Rivet vs Spot Welding

- Heat Affected Zone & Material Compatibility: SPR Riveting is a cold joining process that avoids high temperatures, eliminating concerns about thermal deformation or heat affected zones. Spot welding is a fusion welding process with a narrower process window for aluminum, high-strength steel, and multi-layer structures.

- Impact on Surface Coatings: SPR Rivets cause minimal damage to surface coatings and anti-corrosion layers, helping preserve original corrosion resistance. Spot welding damages coatings and plating, often requiring additional post-weld anti-corrosion treatment.

- Energy consumption and equipment requirements: Spot welding consumes more energy in aluminum and thick plate applications, demanding higher power supplies and cooling systems. SPR Rivet’s energy consumption primarily stems from mechanical pressure, making it easier to integrate into automated production lines.

- Quality consistency: Spot welding quality is significantly affected by material surface condition, electrode wear, and parameter fluctuations. SPR Rivet forming is controlled by dies and equipment, ensuring greater consistency.

SPR Rivet vs Flow Drill Screw (FDS)

- Different Joining Mechanisms: SPR Rivets form mechanical interlocking through plastic deformation without relying on threads. FDS creates threads via hot friction drilling and locks with torque.

- Process Control Dependency: FDS is highly sensitive to material thickness, hardness, and torque control; parameter fluctuations may cause inconsistent thread quality. SPR Rivets require no torque control, offering more predictable connection quality.

- Long-Term Reliability: FDS carries a risk of thread loosening under vibration and cyclic loading. SPR Rivet employs a permanent mechanical locking structure, offering more stable vibration resistance and fatigue performance.

- Assembly Consistency: SPR Rivet’s forming process is directly controlled by equipment, making it suitable for highly automated production. FDS consistency relies more heavily on the torque system and thread formation quality.

Have More Questions?

Contact our engineers for reliable product data and engineering advice.

How to Choose

How to Choose Self Piercing Rivets(SPR Rivet)

Selecting the appropriate Self Piercing Rivet (SPR Rivet) is critical to ensuring joint strength, assembly consistency, and long-term reliability. SPR Rivets are not a “one-size-fits-all” solution; their selection must be based on a systematic evaluation of material, thickness, and assembly conditions.

1. Confirm Total Sheet Stack Thickness

First, determine the total thickness (Stack Thickness) of the sheets to be joined. SPR Rivet length is typically directly related to this total thickness.

In practical applications, common SPR Rivet diameters range from 3.2–5.3 mm, with lengths typically between 5–13 mm. Rivets that are too short fail to form effective locking; those that are too long may cause base material fracture or poor forming.

2. Identify Base Material and Stack Order

Clearly defining the material type and stacking sequence of the sheets is crucial. SPR Rivets rely on plastic deformation of the base material to achieve mechanical locking, so the base material must possess sufficient ductility.

For example, aluminum-aluminum or aluminum-steel combinations are common, typically using aluminum as the base material. If the base material is high-strength steel with insufficient ductility, careful evaluation or process validation is required.

3. Select Rivet Material

SPR Rivets are typically manufactured from alloy steel to meet strength requirements during the punching and forming processes. Different material combinations demand varying levels of rivet strength and toughness. Therefore, the rivet material should be matched to the joined materials to prevent insufficient rivet deformation or excessive damage to the sheets.

4. Choose Rivet Length and Diameter

The length and diameter of the rivet must be selected based on the combined thickness of the plates and the strength of the materials. Generally, thicker plates or higher-strength materials require longer or larger-diameter SPR Rivets to ensure sufficient lock-up depth and joint strength. These parameters are typically finalized through process tables or sample testing.

5. Consider Equipment and Die Compatibility

SPR Rivet selection must also match existing riveting equipment and dies. Different rivet specifications require corresponding punching forces and die structures. Insufficient equipment capacity or mismatched dies directly impact joint quality.

6. Validate Through Testing

Prior to mass production, validate the selection through prototype riveting and cross-section analysis. Inspecting the locking pattern, base material deformation, and absence of cracks constitutes standard engineering validation procedures.

APPLICATIONS

Typical Applications of SPR Rivets

Automotive Body-in-White (BIW)

SPR Rivets are widely used in automotive body-in-white structures, enabling highly consistent connections in aluminum and high-strength steel combinations. They meet the automotive industry’s stringent requirements for structural strength and production cycle times.

EV Battery Enclosures

In electric vehicle battery enclosures, SPR Rivets connect multi-layer aluminum and dissimilar materials, minimizing thermal impact while maintaining structural integrity to enhance safety and reliability.

Lightweight Structures

For lightweight structural components, SPR Rivets provide stable connections without compromising material properties, serving as an effective alternative to welding and traditional fasteners.

Transportation Equipment

In rail transit, commercial vehicles, and transport equipment, SPR Rivets withstand vibration and cyclic loads, making them suitable for applications demanding consistent joint integrity and durability.

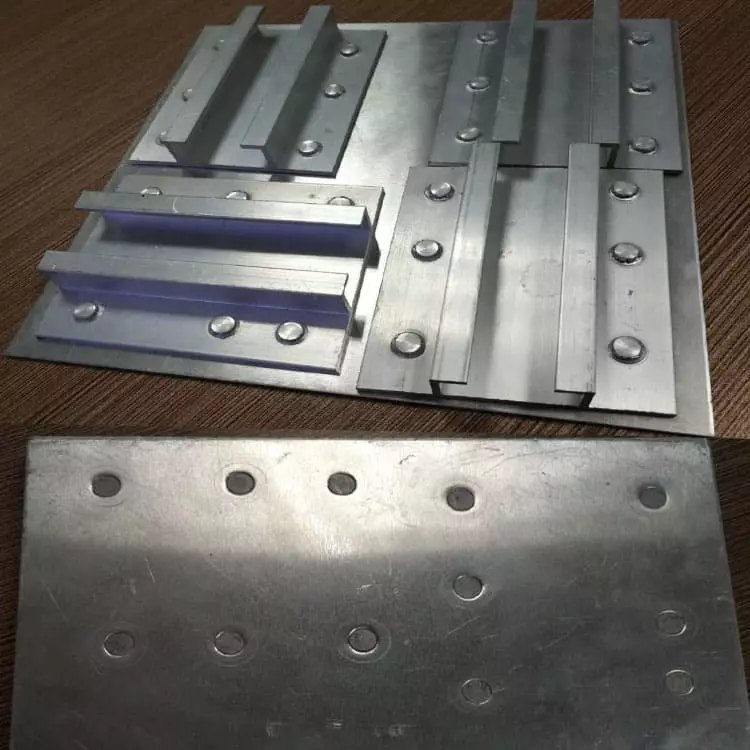

Industrial Sheet Metal Assembly

SPR Rivets are suitable for industrial sheet metal assembly, reducing drilling processes, improving assembly efficiency, and maintaining connection stability in mass production.

Coated and Pre-Finished Panels

For pre-coated or plated panels, SPR Rivets utilize a cold joining process that minimizes damage to surface coatings, helping preserve the material’s corrosion resistance.

FAQs – SPR Rivet

Q1. Is an SPR Rivet Suitable for Blind Installation?

SPR Rivets are generally not considered traditional blind fasteners. Their installation requires specialized equipment and tooling, along with control over the forming process of the base material. Therefore, they are typically used in controlled assembly stations and automated production lines, rather than in completely inaccessible blind installation scenarios.

Q2. Does an SPR Rivet Penetrate the Bottom Material?

No. During installation, the SPR Rivet penetrates only the top layer material. The bottom layer undergoes plastic flow to form a locking structure without being pierced, thus preserving its structural integrity.

Q3. What Are the Advantages of SPR Rivets Compared to Welding?

SPR riveting is a cold joining process that produces no heat-affected zone, causing minimal damage to material properties and surface coatings. It is particularly suited for joining aluminum and dissimilar materials, offering high consistency in connections and suitability for automation and mass production.

Q4. What Material Hardness Is Required for SPR Rivets?

SPR Rivets impose specific requirements on material hardness and ductility. The base material must possess sufficient plasticity to achieve the forming lock. For ultra-high-strength steels with poor ductility, process validation is typically necessary.

Q5. Can SPR Rivets Be Used for Multi-Layer Sheet Metal?

Yes. SPR Rivets are suitable for multi-layer sheet metal connections. As long as the base material thickness and ductility meet forming requirements, a stable mechanical interlocking structure can still be achieved.